Scraping WE130 jaws at 15 degrees

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Basic Techniques and Sharpening Strategies › Scraping WE130 jaws at 15 degrees

- This topic has 7 replies, 3 voices, and was last updated 02/04/2018 at 6:56 am by

Organic.

Organic.

-

AuthorPosts

-

02/03/2018 at 4:26 pm #45009

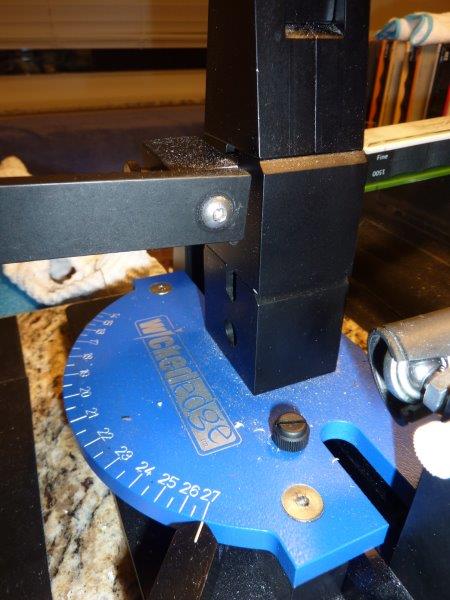

Hi from Australia. I recently got a WE130 and all the trimmings – extra stones, strops, and even the low angle adapter. However, when I try to sharpen my Mora knives, for example, at 15 degrees per side, I find I’m not even touching the blade with the right-sided stone – I’m putting a beautiful polish on the jaws of the “chuck”. And if I use the low angle adapter and long rods, I still can’t quite get down to 15 degrees.

I’m adjusting the angle using the slide plus the micro-adjuster, and using the magnetic cube on the outside of the stone leaning against the blade. Or at least – it SHOULD be leaning against the blade. But on the left it JUST misses the chuck jaw, and on the right it is leaning on the chuck jaw with a distinct gap between the stone and the blade edge.

I have the Mora set in the jaws using the upper pair of holes, and even tried eyeballing it even shallower. The Moras have a Scandi grind, but there’s no way I can conform to that on the WE130, so I’m happy to put a new bevel on the edge. Or would be, if I could stop polishing the chuck jaw…! 😉

Any clues? These are all standard Mora knives, set as high as possible while still keeping them firmly held, and using the cube to set the angle on each side. But 15 degrees is proving very elusive, but is what I want to get. 🙁

Oh, and I have a Benchmade 940 too – but I’m not game to try that one on the WE130 in case I screw up the blade.

02/03/2018 at 4:50 pm #45010Welcome to the Forum and the WE Community, Pete. I’m sorry to say, there are limitations depending on the size and shape knife of the lowest bevel angle you can achieve with the WE130. Obviously you found it. You might try a Tormek Small knife adapter with the LAA. The other resolution, which is a little more involved, but will surely help, is to add a “riser block” between your base and the vice base where they screw together. That will increase the distance between you rod arm swivel joints and the jaws top. The higher the jaws top and the more distance between the swivel joints and the jaws, the lower an angle you’ll achieve.

I obtained my “Riser block” from WE. Many people have made them from anything from wood to aluminum.

No fault of yours, you happened to pick a very special and difficult ground knife to sharpen. I hope I was able to provide you some options even though I didn’t give you the instant fix.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

02/03/2018 at 5:19 pm #45012Wow – that was quick 🙂 Thank you for the reply. Yes, a riser block would make sense based on the geometry. I have my WE130 mounted on a heavy piece of thick (2″) timber, and some non-slip material glued underneath. And yes, I do have a Tormek T8 system, including the small knife adapter – I might take your suggestion and try that. Adding a riser block would require me to use much longer screws up through the base, so the Tormek thing may be the way to go. I’ll give it a try.

Thanks again for such a prompt response – appreciated 🙂

02/03/2018 at 5:37 pm #45013Yes Pete, I did need longer, fine-thread screws. You don’t need to use hex flat head cap screws, (like WE provides). You can just use fine thread Phillips Flat heads. I’m pretty sure they are 10/32″ threads. Or really, anything that you can counter sink flush into your base so it doesn’t get in the way would work.

I also needed longer guide rod arms to take advantage of the height increase. I’m using 12″ now. I do see a need for 13″ or 14″ too, for wide profile tall bladed Chef’s knives, sharpened to low bevel angles. The long guide arms do get unwieldy so it takes some practice to get use to using them.

One thing you’ll need to be aware of, using the Tormek Small Knife Jig with the LAA, is recording the clamping position. You’ll need to use it again for future sharpenings.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

02/03/2018 at 6:12 pm #45014Thank you again. It’s almost like a “race to the top”, isn’t it? The higher we make the holder, the longer the rods need to be, and the higher we go, the progressively smaller reduction in angle we achieve. An exponential curve, in fact 🙂

Maybe when I’ve polished enough metal off the chuck jaws, I’ll be able to get the perfect 15 degree angle? 😉

I’m wondering also if the Scandi grind on the Mora knives may be contributing, due to the tapered nature of so much of the blade? The chuck jaws are clamping onto something that is angled on both sides, so some tilt to one side wouldn’t be difficult, despite me trying to get it straight. I’ve even used slivers of wood as shims to try to get that. But I still have one of the world’s best polished chuck jaws…! And that’s despite making sure I’m not clamping onto the Scandi-ground portion of the blade.

Ah well – it’s all a learning experience. The edges I’ve achieved on knives with bigger blades is to die for, though – it’s just that all my Mora, Hultefors, Buck, Spyderco, and other bush knives have smaller blades.

1 user thanked author for this post.

02/03/2018 at 6:18 pm #45015I agree it probably wouldn’t hurt to thin the jaws, chuck (as you call it) a bit. I suggest you paint over the polished area(s) with a black sharpie to help you keep track if it’s happening again, so you can take steps to try to avoid it.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

02/03/2018 at 10:52 pm #45021Update: I just used the Tormek small knife jig, and it worked at 15 degrees OK. And yes, I recorded where I clamped the knife holder, and also the knife. I used it for one of my Moras and it gave me hair-whittling sharp at 15 degrees per side.

So I took the plunge with my beloved Benchmade 940 and used the Tormek jig for that too. Apart from some blade flex, which I controlled by using VERY light strokes on the WE130 stones and strops, I managed to get that one scary sharp too.

Thanks for that suggestion – the Tormek small knife jig now lives with my Wicked Edge kit 🙂

3 users thanked author for this post.

02/04/2018 at 6:56 am #45024There are quite a few of us who purchased the small knife jig to use with the WE. It really comes in handy when the clamp isn’t working out. I’m glad you were able to get your issue resolved.

3 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.