Realigning Deformed Edges

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Basic Techniques and Sharpening Strategies › Realigning Deformed Edges

- This topic has 6 replies, 4 voices, and was last updated 05/19/2020 at 4:47 pm by

Readheads.

-

AuthorPosts

-

05/08/2020 at 6:21 am #54211

When sharpening my kitchen knives I use the 800 and 1000 diamond stones with edge-trailing strokes. After each stone, I use a few very light, edge-leading strokes to remove any burrs or wire edges that were created by the sharpening process.

After I finish sharpening, I test the edge by push-cutting newspaper. If the edge isn’t where I want it to be, I have been stropping each knife on the cushion on one of my breakfast room chairs. When you are able to stop laughing, please understand that I do my sharpening at the breakfast room table, and the cushion was right there on the chair next to me, so I figured why not. The cushion has some give, and the fabric is a synthetic with a little more roughness than denim. And I often found that light stropping on the chair cushion improved the knife’s ability to cut the newspaper. My assumption is that it is aggressive enough to break off any wire edges, but not aggressive enough to change the angle of the edge.

Now I would like to begin using stropping to realign the edges of my kitchen knives between sharpenings, and thereby extend the edge’s life. I have recently read several posts that discuss this type of stropping, and, if I understood what I have read, either an unloaded leather strop or a smooth steel is the best way to straighten an edge.

Unfortunately, I still have questions despite my research. First, I was wondering if a ceramic rod could be used for both softer steels as well as steels with a higher Rockwell hardness (ie above 62-63HRC), or should an unloaded leather strop be used for softer steels?

I would also like to clarify how close to the knife’s sharpening angle the stropping needs to be? And whether there is more leeway with respect to the stropping angle if a leather strop is used, or if the strop is on a softer substrate (I understand that using a softer substrate may make the edge slightly more convex). I have never mastered free-hand sharpening, which is why I have a WE130.

So any advice that would help me find the most straightforward way to realign the edges on my kitchen knives would be greatly appreciated. I am trying to use unloaded strops, if possible.

Thanks

rummels

05/09/2020 at 11:11 am #54221I have mostly kitchen knives. I have found that doing anything without a jig (WEPS) introduces variability in “finding” the precise bevel to apex plane. If you have a micro bevel then it is even more difficult. Using strops while on the WEPS is also touchy to avoid rolling the edge (ie. most people recommend backing off 1-2 dps to avoid it but then you are using pressure to find the edge with variability). I use a Messermeister white $20 ceramic rod to true up my kitchen knife edges. It is claimed to be 1200 grit but in looking at the scratch patterns under my scope I feel it is coarser than the 1200 WEPS diamond grit (more like 600 to me). I used to use a classic steel but threw it in the trash once I saw how it ripped up the edge under my scope.

Using the white rod freehand (or anything else for that matter) takes practice. I find that only a few very light edge leading strokes on the rod does it. A few hints I found are to hold the rod horizontal with the end resting on something (so the rod doesn’t move) to give you a view of the black marks, pretend you are trying to cut peels out of the rod, listen to the sound carefully (it varies slightly based on contact angle). I go edge leading away from me and flip the knife and go edge leading toward me. You need to be able to see what you are doing.

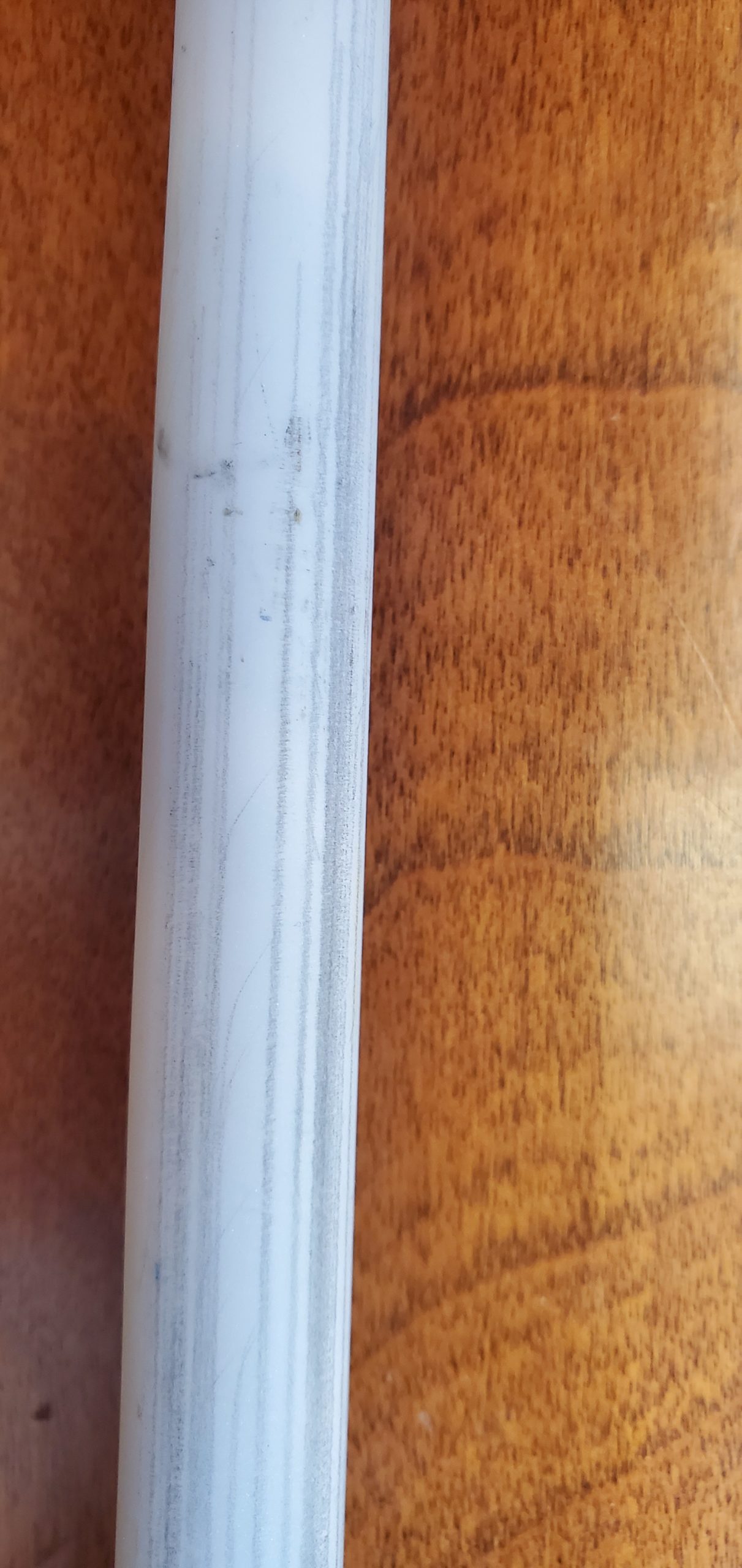

I go straight to a thumb nail scrape (before, during, after) to help me determine progress. The white rod also has the benefit of leaving steel markings with each stroke (see pics). I think the wider black lines are an indication that you have engaged more of the bevel. Note that it is very easy to inadvertently put a micro bevel (say 20 dps) on an edge when you were just trying to straighten a 16 dps bevel. The knife will be sharper than before straightening but not as sharp as it was at 16 dps. This has happened to me a lot (pic 3). I contend that very, very few people can put a freehand bevel/straightening on an edge like a jig can (WEPS). A scope will tell the true results.

It takes years of practice for a straight edge barber to perfect his stropping and he has the advantage of special straight edge geometry to find his angle. It’s about pressure and smooth angular flow (not trivial). I have been at it for a few years now and am not sure if I will ever get there but t sure is fun and interesting. Good Luck. Tom

Attachments:

You must be logged in to access attached files.

05/09/2020 at 3:04 pm #54226I had the same idea, bought the leather, made the paddle and tried to fix the edge as I saw the shinny spots.. but in the end, I think I just dulled the entire knife as I can not hold the needed angle.. that’s why I have a WE 🙂 It really takes less time to mount the knife and hit it with a 1000 grit stone and be done with it once the knife stops cutting how you want it. But I guess if you can hold the correct angle it would extend the time..

05/09/2020 at 9:31 pm #54227I use a Spyderco sharpmaker for quick touch ups. It is inexpensive and a couple of passes on each side brings back a great edge. Done in a minute. Issue is it is fixed to 20 and 15 degrees when using the base. I use it on my edcs which I typically sharpen at 15 dps. Never used it on my kitchen knives which are typically sharpened at a lower angle but the sharpmaker stones could be used in the same fashion as a traditional steel.

05/10/2020 at 11:48 pm #54228<p style=”text-align: left;”>Doesnt spyderco have the same issues as a handle held ceramic rod.</p>

05/15/2020 at 7:23 am #54236Thanks to all for your input. I have concluded that using something similar to the Sharpmaker will be the best approach for me. I have a multi-angle drill guide, so I am going to make a base for the Sharpmaker’s ceramic rods that will hold them at angles that are very close to my sharpening angles.

05/19/2020 at 4:47 pm #54279How about this: drill 2 opposite side square holes to fit a WEPS paddle at say 16 and 18 degs so we can use any of our paddles instead of a ceramic. I find that under a scope those ceramics put a much coarser scratch pattern than the 1200 grit they claim. Ceramic is just different. Then if you can devise an easy attachment to hold the blade vertical (a real key to me), then you might really have something for quick true ups.

-

AuthorPosts

- You must be logged in to reply to this topic.