Problem with low angle adapter

Recent › Forums › Main Forum › Getting Started › Problem with low angle adapter

- This topic has 32 replies, 7 voices, and was last updated 04/23/2014 at 4:11 pm by

Josh.

Josh.

-

AuthorPosts

-

04/19/2014 at 7:41 am #18334

I’m curious ( I swear I’m not being a jerk) did the knife get sharp or was the geometry off and not able to apex the edge?

04/19/2014 at 2:03 pm #18335Clay,

thanks for the reply but that’s not it. I get the principle – the cube is always leaning to its left so it removes any difference when it leans to its right. Right here I’m not trying to measure the angle of the stones but checking the verticality of the blade in the vice. I’m measuring (in this case) a lean of 2.1 degrees to the left when the cube is on the right side of the blade as I look at it, leaning to its left. On the left side of the blade it’s leaning 0.5 degrees to the left. If I flip it 180 degrees it reads 0.6 degrees. So the knife is inclined 1.3 degrees from the vertical in the vice. That means that when the cube is showing 12 degrees on either side on the stones I’m really getting 13.3 and 10.7 degrees. Can I just accept that the blade is tilted and add/subtract 1.3 degrees to/from the right and left sides or is the geometry more complex than that?

Regards,

Gerald.You can absolutely do this with no worries… I have done it myself several times =)

But there is one thing that no one has mentioned in this thread yet… take the knife out of your vise and take the screws out. put the vise all the way together… do you have a gap at the top? it should be flat all the way to the tip of the vise. sometimes the vise bends at the top which can cause these kind of issues.

04/19/2014 at 11:31 pm #18338Eamon,

I’ve done several knives. They’ve all been sharp. What I was consistently finding when sharpening 50/50 was that the left hand stone would not raise a burr when the right stone would. In one case five passes of the left stone would not even remove the burr left by the right! Yesterday I did two Tojiro Senkou chef’s knives. Tojiro apparently factory grind their knives 60/40 so I did the maths and tried that. The bevels didn’t look 60/40 but both knives shaved my arm and shaved printer paper.

All the best,

Gerald.04/19/2014 at 11:40 pm #18339Josh,

this is becoming a bit of a PITA. If I do what I thought was the correct maths and sharpen 50/50 I still get an uneven bevel. What I have to do is to estimate the difference between the angles and see how much magic marker gets taken off on each side, then readjust. Even then I don’t get exactly even bevels.

Regarding the vice, if I do as you suggest I can run a fingernail along the groove between the jaws at the top but cannot push a nail into any gap. I can, however, see a tiny chink of light between the jaws lower down. If I HAVE bent a jaw should I take the whole thing apart and sand the bent one flat again? I should think it would have to be the static one as I cannot get the moving one to rock when put flat on the granite.

Btw, can you explain to me how it is that when I have visibly removed metal right to the edge on both sides the I cannot raise a burr on the left side when one or two strokes with the right gives a substantial burr?

TIA,

Gerald.04/20/2014 at 1:26 am #18340Josh,

this is becoming a bit of a PITA. If I do what I thought was the correct maths and sharpen 50/50 I still get an uneven bevel. What I have to do is to estimate the difference between the angles and see how much magic marker gets taken off on each side, then readjust. Even then I don’t get exactly even bevels.

Regarding the vice, if I do as you suggest I can run a fingernail along the groove between the jaws at the top but cannot push a nail into any gap. I can, however, see a tiny chink of light between the jaws lower down. If I HAVE bent a jaw should I take the whole thing apart and sand the bent one flat again? I should think it would have to be the static one as I cannot get the moving one to rock when put flat on the granite.

Btw, can you explain to me how it is that when I have visibly removed metal right to the edge on both sides the I cannot raise a burr on the left side when one or two strokes with the right gives a substantial burr?

TIA,

Gerald.I think your main vise is bent and/or possibly your LAA vise is bent… take some pics and post them if you can. If so WE will replace them, just get w/ Clay or Kyle.

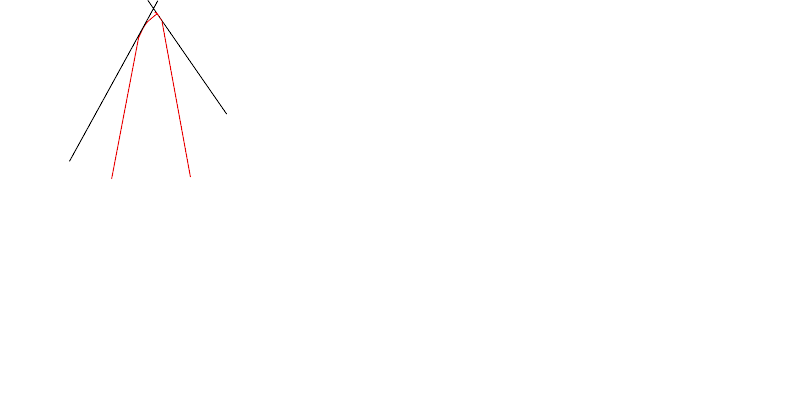

Sure, I can explain it to you about the burr on one side but not the other 😉 it happens to me quite frequently. Hopefully these pictures will explain. In the second one you will notice a little curl at the very edge… this signifies a burr. You may be grinded to an “apex” on one side but haven’t fully reached it on the other. The black lines signify your stones. Understand? =) Hope this helps!

04/20/2014 at 1:57 am #18341

04/20/2014 at 1:57 am #18341Josh,

I see that (and have seen it!) but it does not match the case where I can see sharpening right to the edge on both sides, no?

I’m grateful for your offer to replace parts which I have damaged, but I have to pay tax on the value of the goods AND the shipping for anything sent here from the States. I shall be there in October (or even in transit at MIA on the 29th inst.) so we can sort it then. In the meantime can I not just flatten the bent items with 1000 grit wet and dry?

All the best,

Gerald.04/20/2014 at 2:15 am #18342I don’t work for wicked edge, Gerald 🙂 I was saying that they will take care of you and you need to get with their team to get it worked out… If it is bent then they will send you a new one.

So is your vise indeed bent?

Josh

04/20/2014 at 2:51 am #18348Josh,

take a look. These pictures are taken using my $30 supposedly 200x microscope.What would you say? Btw, I mistook WE for we in your last post!

Gerald.04/20/2014 at 4:44 am #18349Np!

I can’t really tell unless it is zoomed out 🙂 it should look similar to this (although mine is made from tool steel)

Josh

04/20/2014 at 12:06 pm #18350Excellent observations, Josh.

But back to the issue of the knife leaning to one side. I have a couple of knives now that present this same problem. Their flat grinds don’t allow the vise to be used normally. Gwelsby is right on about needing to add or subtract the lean angle from the sharpening angle. I know others use a patch of chamois, but I use a patch of coarse paper towel to improve the grip on the blade. My Spyderco Delica in ZDP-189 has the same tilt problem with a total of 3.5 degrees included between the flats. I clamp the blade flat against the left jaw and push the moveable jaw out until it is parallel to the right face of the blade. I then use a 1.75 degree offset, depending on the actual angle I find at the blade flats.

Unfortunately, if you want to match the existing bevels and there are no flats to clamp on, you’ll need to check the blade’s position for tilt in the clamp. And/or resort to the Sharpie method to confirm the angle.

BTW Gwelsby, have you checked to be sure that the blade is not rocking from side to side as you sharpen it? I have to admit having this bite me in the butt. Having been burned once, now when I clamp a blade I check to see that it is clamped securely by trying to rock the blade in both axes.

04/20/2014 at 1:02 pm #18351Was your tool steel vice a lot to have fabricated Josh? It seems to be a great solution to avoid bending a vice I guess you could even have it tapped with bigger threads to allow more torque to the clamp bolts .

04/20/2014 at 3:51 pm #18352Thanks for that tcmeyer. I have been fortunate enough to have been asked to sharpen a truly FFG chef’s knife. It is a block of steel 1.75mm thick with the edge ground out of it. I replaced the chamois with kitchen paper as you suggested and bingo! 0.0 degrees on either side! I’ve not tried replacing the chamois on the other knives yet but it would seem that the problem arises when trying to clamp a knife which tapers from the bottom to the top of the vice. Mind you, see my photos in reply to Josh in my next post.

Thanks again,

Gerald.04/20/2014 at 4:22 pm #18355Josh,

well, if you’re using tool steel then the problem is not your vice’s getting bent! A couple of photos with less magnification.There may be minor issues there BUT. The left jaw of the vice is fixed and vertical so WHENEVER a tapered blade is clamped and the left side of the blade is flush against the jaw it will ALWAYS tilt to the left, at the included taper angle of the blade. This does not, of course, explain how I got the left side of the blade leaning to the left, as it should be vertical. Perhaps it may be explained by the use of chamois.

So, the solution SHOULD be: For all blades, make sure the left side is vertical. For FFG blades, just use the angle cube to set the angles. For tapered blades find the included taper angle by lying it flat on the granite and using the angle cube, then do the maths. If you want asymmetric bevels, do some more maths! Oh, and probably use kitchen paper instead of chamois.

Regards,

Gerald.04/21/2014 at 4:52 pm #18359Excellent observations, Josh.

But back to the issue of the knife leaning to one side. I have a couple of knives now that present this same problem. Their flat grinds don’t allow the vise to be used normally. Gwelsby is right on about needing to add or subtract the lean angle from the sharpening angle. I know others use a patch of chamois, but I use a patch of coarse paper towel to improve the grip on the blade. My Spyderco Delica in ZDP-189 has the same tilt problem with a total of 3.5 degrees included between the flats. I clamp the blade flat against the left jaw and push the moveable jaw out until it is parallel to the right face of the blade. I then use a 1.75 degree offset, depending on the actual angle I find at the blade flats.

Unfortunately, if you want to match the existing bevels and there are no flats to clamp on, you’ll need to check the blade’s position for tilt in the clamp. And/or resort to the Sharpie method to confirm the angle.

BTW Gwelsby, have you checked to be sure that the blade is not rocking from side to side as you sharpen it? I have to admit having this bite me in the butt. Having been burned once, now when I clamp a blade I check to see that it is clamped securely by trying to rock the blade in both axes.

I totally understand what you are saying TC but you definitely can still use it normally. I just did this para 2 on my wicked edge after regrinding it 🙂 no issues.

Check out my video on clamping… It has always worked great for me…

Was your tool steel vice a lot to have fabricated Josh? It seems to be a great solution to avoid bending a vice I guess you could even have it tapped with bigger threads to allow more torque to the clamp bolts .

Around $130…but you have to find someone willing to do it.

Josh,

well, if you’re using tool steel then the problem is not your vice’s getting bent! A couple of photos with less magnification.There may be minor issues there BUT. The left jaw of the vice is fixed and vertical so WHENEVER a tapered blade is clamped and the left side of the blade is flush against the jaw it will ALWAYS tilt to the left, at the included taper angle of the blade. This does not, of course, explain how I got the left side of the blade leaning to the left, as it should be vertical. Perhaps it may be explained by the use of chamois.

So, the solution SHOULD be: For all blades, make sure the left side is vertical. For FFG blades, just use the angle cube to set the angles. For tapered blades find the included taper angle by lying it flat on the granite and using the angle cube, then do the maths. If you want asymmetric bevels, do some more maths! Oh, and probably use kitchen paper instead of chamois.

Regards,

Gerald.My vise isn’t bent Gerald 🙂 I was showing you what it should look like. My suspicion is that your knife was rocking back and forth as stated above, while you were sharpening maybe? Anyway, glad you got it fixed!

Josh

04/21/2014 at 7:04 pm #18362Josh,

I should have been clearer. What I meant was that if you were getting the same symptoms as I was (tilting blade) then it was NOT because your vice was bent so there must be another explanation.

Regards,

Gerald. -

AuthorPosts

- You must be logged in to reply to this topic.