Market Lapping Film Differences

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › Market Lapping Film Differences

- This topic has 23 replies, 8 voices, and was last updated 12/29/2016 at 9:37 am by

Kyle Kaplan.

-

AuthorPosts

-

11/24/2016 at 6:17 am #35977

Hello all… Happy Thanksgiving!

I was wondering… has anyone independently compared the different lapping films on the market for polishing? Namely; Aluminum Oxide, Silicon Carbide and of course the Diamond?

Does anyone know the physical difference and the properties of each? I have ordered some WE Aluminum Oxide lapping films for comparison and I have been using all the WE Diamond Lapping films for months now.

I’m almost embarrassed to frame this question on this forum, because, I have some other lapping films from a (WE Competitor- Edge Pro Inc.) which are not labeled like the WE diamond lapping films but polish amazingly from personal observation. I believe they are are 9u, 3u, and .25u (labeled 2k Grit, 3k Grit and 6K grit) maybe.

They seem to have different characteristics which bring out a brilliant shine that I can’t yet explain but have observed. In other words; through observation, these three lapping films put a polish on a blade that I can’t seem to duplicate with all of the WE lapping films used in progression from top to bottom, I am not too sure why. Maybe you can help. They just happen to be significantly cheaper but the purpose of my inquiry is that they seem to provide a better polish than anything else I have found. The mystery has been bugging me.

Does anyone happen to know what they are made of and the substrate used on them?

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162211/24/2016 at 7:26 am #35978Another question: Some film sets include papers with 15, 20, 25, 30 micron. Did you compare film vs. diamond stones? Microns supposed to convert to grit values like 15µ = 1200, 20µ = 1000, 25µ = 800, 30µ = 600. Would be interesting to compare 20µ film with 1000 grit diamond stone, 25µ film with 800 grit diamond stone, 30µ film with 600 grit diamond stone. Happy Thanksgiving!

11/24/2016 at 7:40 am #35979On the Edge Pro site they make this claim which is where I got my numbers…

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

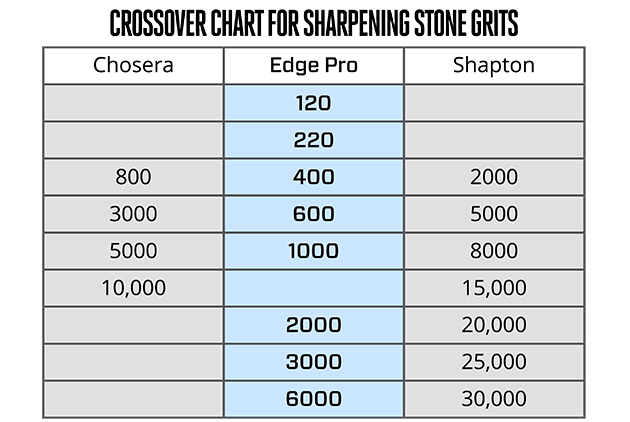

11/24/2016 at 7:45 am #35981I also have this chart which makes the references “somewhat” clear.Universal-GRITCHART

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

11/24/2016 at 2:28 pm #35989I am somewhat flustered by the differences between the various standards groups. Why the differences? What do they mean? Which applies to us?

So I prefer something that makes sense to me; I use the number of particles per inch (PPI*). Something interesting I’ve found is that the film grit progressions we most often use – and by experience have found to be successful – show between 1.5 and 2.0 ratios between the PPI for one grit and the PPI for the previous grit.

For example, my chart shows the following ratios for the films I use:

15/9 = 1.67

9/6 = 1.50

6/3 = 2.00

3/1.5 = 2.00

1.5/1.0 = 1.50

1.0/0.5 = 2.00.

I bring this up because I think that testing would show that these progressions are too conservative. The films are manufactured to polish highly critical components such as optical fiber connections, but for us, when you get down to micron film it’s hard to see scratches. We tend to judge a polish job by its reflectivity. I suspect we could spread the sequences out with ratios of 3:1 or perhaps even 4:1 from grit to grit and still achieve the same reflectivity.

*PPI = 25400 microns per inch / particle size in microns

1 user thanked author for this post.

11/24/2016 at 4:11 pm #35992I agree with your progression ratio analysis Tom. I have been eliminating some of the steps in my progression for the reason you indicate above, but still can’t figure out what is going on with these foreign polishing tapes from Edge Pro. I’ve “heard” the word “burnishing” thrown around on this forum in the past with regard to the leather strops and diamond paste. I think something like that might be going on with these other polishing tapes. The characteristics of the polishing and the deposition of metal on the tape is significantly different than the WE diamond lapping film . It’s almost like the metal is “smearing” and not “flaking” like the WE diamond lapping films. I can clean the diamond tapes with rubbing alcohol and a cotton ball and they almost come out like new, however, the foreign polishing tapes will clean up but they won’t come completely clean after the first use. The diamond film has a translucent PSA backing (I think) and the Edge Pro tapes have something that is more opaque. They seem to load up a lot more and have very different characteristics, which is why I’m trying to figure out what they are. The reflective finish that results on the blade is very different as well and isn’t something I could capture in a photograph due to the subtle uniqueness. I am sure I am seeing something different in my finished blade. I haven’t really decided if it’s better or not but it’s different and took less work. I was hoping somebody else may have made this observation or is willing to try it and observe for themselves. I needed to trim them a little bit to fit on the WE paddles. I am using the glass platens. The end results are reproducible and very different. The reflection of light off the blade when finished almost has a different hue (Like a Mylar electrostatic bag) when done. One would only need these three tapes (2k, 3k, 6k from Edge Pro- Click Here to View Site) to get the result which could be a significant cost savings. I have ordered some more ($9.00 for 15 (Each grit). I would be willing to mail some off for testing or a second opinion. Eddie (M1rrorEdge)

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

11/25/2016 at 12:17 am #35993All;

I just received a pleasant update. I contacted Ben Dale (The Owner of Edge Pro) and am surprised to have gotten a response back on Thanksgiving. He says the 2K and 6K polishing tapes are Silicon Carbide and the 3K tape is Aluminum oxide. I must say, I wasn’t expecting that. It may start to explain what I have been seeing. Without my light box, I was able to take a pretty good photo of a recent knife polished with these tapes on a Wicked Edge Field and Sport Pro. It doesn’t show the “Mylar electrostatic bag” color effect but you can see the highly reflective result of the three polishing tapes after the Ultra Fine 1000 grit Stone. The Knife is a highly used/Military abused “A-Symmetric” or “Chisel ground” M16-14ZSF by CRKT. The owner of the tool happens to be a contractor working on a military installation in Southwest Asia. This knife was designed with the desert and needs of our coalition forces in mind. The problem I see with it is… once it is dropped out here, you may never find it. When I received it for sharpening, it was just a mess. It blew him away when I gave it back, which, is why I love sharpening out here.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16223 users thanked author for this post.

11/25/2016 at 11:50 am #36005It looks great. But does it look greater than after a proper job with the WE diamond lapping films? What do you think? It’s very hard to judge from a photograph. Als WE make ALU oxide lapping film, I’m curious if anyone has any experience with it.

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/25/2016 at 2:29 pm #36009Hey guys, we just released our Aluminum Oxide Lapping Films earlier this week. I got to play around with them a couple weeks ago and I found the results to be very similar to the Diamond Lapping Film. The big difference was the time it took. The Aluminum Oxide Films took about 1.5-1.75 times longer to achieve the same results as the diamond. I didn’t notice a burnishing effect like what strops do, but maybe that’s because in my mind I was comparing them to the diamond films, not strops, and I hadn’t considered a burnishing effect at all. I’ll do a test to compare the 5 micron Aluminum Oxide, 6 Micron Diamond, and the 5 Micron leather strops, and let you know what I find.

11/25/2016 at 5:15 pm #36010OK, I sharpened and tested 3 razor blades. One with 5 Micron Aluminum Oxide, one with 6 Micron Diamond Lapping Film, and one with a 5 Micron Leather Strop. First I sharpened each of them with 50 strokes per side with each 800, 1000, and 1500 grit diamond stones so they would all be equal from the start. I measured the sharpness of each razor blade in our sharpness testing machine. It measures how many grams of force it takes to cut through a medium; the lower the number, the sharper the edge. I took four measurements for each test. Here’s are the results:

5 Micron Aluminum Oxide Film

Initial sharpness of razor after 1500 grit stone: 372, 298, 407, 381 grams

Sharpness after 50 strokes per side with 5 micron aluminum oxide film: 315, 307, 317, 381 grams (315.25 avg)

Average sharpness increase: 49.5 less grams of force needed to cut medium

6 Micron Diamond Lapping Film

Initial sharpness of razor after 1500 grit stone: 390, 357, 369, 362 grams

Sharpness after 50 strokes per side with 6 micron diamond film: 282, 307, 286, 289 grams (291 avg)

Average sharpness increase: 78.5 less grams of force needed to cut medium

Leather Strop with 5 Micron Diamond Paste

Initial sharpness of razor after 1500 grit stone: 330, 337, 332, 369 grams

Sharpness after 50 strokes per side with 5 micron leather strop: 285, 324, 293, 277 (294.75 avg)

Average sharpness increase: 47.25 less grams of force needed to cut medium

In terms of overall sharpness they were very similar, but the 6 Micron Diamond Lapping Film had the best increase in sharpness. Personally I think the finish on the 6 micron diamond film was the best, but the 5 micron aluminum oxide wasn’t far behind. The leather was very milky looking in comparison. These photos were taken with a 60x magnification loupe that attaches to a phone. (hopefully I can get Clay involved and use his microscope next week) From what I can tell the edges sharpened by the films have more defined scratch marks, and the leather’s edge is more blurry, indicating it is burnishing and the films are not. We’ll know for sure when we see them under the microscope.

Attachments:

You must be logged in to access attached files.

6 users thanked author for this post.

11/26/2016 at 2:03 am #36017Thanks Kyle! I was particularly interested in the ALU oxide film (since I own the other two). It doesn’t surprise me that it’s less effective than the diamond film, although I still have some questions based on the other topic started by MirrorEdge.

The comparison between the diamond lapping film and the strops is consistent with my observations. Now I only use my strops for very fine compound (< 0.5 mu).

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/26/2016 at 4:49 am #36020M1rrorEdge, Nicely done! Dang, a chiseled edge with a tanto profile with serrations. I have never sharpened a knife with all of those characteristics combined on the same knife. Plus, you put the mirror edge on it with lapping films. You are obviously more than up to the challenge. Did you stay with one bevel angle or does it also have a micro bevel?

11/26/2016 at 8:43 am #36023By the way, how did you polish the serrations, Eddie?

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/26/2016 at 1:00 pm #36026By the way, how did you polish the serrations, Eddie?

Fortunately for me and the owner of this tool, the serrated points where not damaged and the cutting surfaces where still sharp on the inside, so, no sharpening was necessary this time. All I did do was some polishing with the lapping films to help match the primary edge. I do this by wrapping the lapping film on wooded dowels of corresponding serration sizes. This can be done with wet dry sandpaper as well.

If the serrations needed to be sharpened, I would only sharpen the back at a really low angle trying not to create a burr on the front side. I would then run a circular ceramic of similar dimensions over the front to remove any burr (that I did create) and then follow up with the lapping film treatment referenced above until I get the desired result. Any other technique and you run the risk of damaging the serration tips.

I can’t say this is my idea. I learned how to sharpen serrations from the legend-Tom Veff at Columbia River Knife and Tools. He has now shared this with the world and even created his own sharpening tool and something called Veff serrations, so, I will post his video here .

I must note: I have modified Toms technique a little and only use it for polishing now as referenced above. However, if your patient and take your time, you can sharpen and repair the serrations this way too like Tom shows you in the video.

I learned from a different “legend” to sharpen serrations from the back only with light burr removal from the front, however, for polishing, I use Toms technique shown in the video exactly except with lapping films.

Did you stay with one bevel angle or does it also have a micro bevel?

No micro bevel on this one. Both parts of the Tanto section are the same angle. I needed to sharpen one part at a time with a minor readjustment in-between. The back “Flat” has a tiny but not a true micro bevel. So it’s really not a traditional chisel. I just matched what CRKT put on the edge. Based on how I got it, this was probably a good idea. This knife was a challenge but I enjoyed doing it.

If you find this helpful, please let me know. I thought Clay was working on something for serrations for the Wicked Edge… I wonder how it is coming??

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

11/26/2016 at 2:32 pm #36027Thanks! You always seem to have great posts…. I usually learn something new. I also appreciate the links you embed. You and others make this forum worth reading and posting.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.