I think I am doing something wrong.

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Basic Techniques and Sharpening Strategies › I think I am doing something wrong.

- This topic has 5 replies, 3 voices, and was last updated 08/28/2018 at 12:43 am by

Ralf.

-

AuthorPosts

-

08/23/2018 at 1:05 am #47441

Hi guys.

I got a Gen3 Pro for my birthday and got all accessories I need now. But on leather I got some issues, but let me start.

i search my angle with sharpie, once I got it I start from the grit needed, let’s say “first time” sharping 100/200, 400/600, 800/1000

Then my Problem starts, which one next? 1500diamond or 1200/1600 ceramic?

after those (I use them always different) I go over to micro ceramics, which makes another problem the coarse side feels and the blade looks as it cuts harder than 1500/1600, can that be true?

then I switch to fine micro ceramic which makes the edge nice looking.

then I set the angle 2degrees in and use 4micton leather then 2. Which again feels more aggressive than my ceramic did, also finish does not really change just getting a mess with all that dust from the sprays flying around.

after that I use 1micron and as last step 0,5micron.

the blade looks good but not perfect.

i used Naniwa 400/1000/3000/8000 before and the edges looked a lot smoother.

on my WE I still have scratches and don’t get that mirror I expected.

maybe I bought wrong leather?

Attachments:

You must be logged in to access attached files.

08/23/2018 at 8:09 am #47444Ralf , Welcome to the WE Forum. You present a similar question as most new sharpeners do, essentially what order do I use all these stones and strops I have. First let me invite you to read, read, read through this Forum. This subject is covered in great detail, many times over. To try to attempt to repeat it here I’ll overlook more then I’ll remember. Please read through the forum. I’m not trying to avoid answering your question I’m trying to give you a more rounded discussion than my simple answer will provide.

I will share with you that you don’t have to use everything, that is all the different grits and mediums you have. Your trying to figure out a logical grit progression based on their grit or particle size and it’s not that simple. Different abrasive mediums, of the same grit particle size, give different results…it’s not logical. Generally the diamond progression is followed by a ceramic stone, (either the Superfine 1200/1600, or the microfine 1.4µ/0.6µ,) then finished with a strop progression for polishing and edge fixing/setting.

Since you’re asking this question and your new to post on this Forum, I’ll take a gander that you’re a new user of the Wicked Edge Precision Sharpeners,(WEPS). Along with having new equipment, you have new sharpening stones. There is a general break-in period where the stones after 8 or 10 knives worth of sharpening usually start to come around and perform better, truer and more predictably. (The Ceramics take even longer for their break-in). There is also a “learning curve”, some time period of using the WEPS it takes to gain knowledge , experience and develop a “sharpening technique” that works for you to achieve the results you’re looking for. For some they catch on quickly for others it’s a slower road.

That’s why we recommend you start off this learning process or journey into WEPS sharpening with “beater” knives that you don’t really care about, to learn with and practice on. Save your favorites and collectibles for after you figure this out.

It take adequate time, adequate effort and proper technique to apply the edge you describe you’re looking for. Using the WE isn’t hard and it isn’t simple either.

Ralf please go to the main Forum page, (upper right of this browser window), then find “Basic techniques and sharpening strategies” and read, read, read. It’ll start with the most recent posts in that forum category and go back in time as you click higher page numbers. Try to jump back a ways, a year or two, then read forward the posts titles that appear they may interest you. If you find a post with an author you like to read, click the author’s name and it’ll bring up a list of posts the author wrote. The responses you like, will give you other authors to read.

There are many many YouTube videos on Sharpening with the WE that cover all sorts of subject matter. A simple google serach for “grit progression for Wicked Edge” will give you a lot of good material to read through. Also check out “knowledge base” on the upper right of this browser too. There’s a tremendous amount of good material and videos there too.

Marc

(MarcH's Rack-Its)5 users thanked author for this post.

08/23/2018 at 2:33 pm #47447Thank you.

is there maybe a chart which can make it “logical” ?

08/23/2018 at 3:43 pm #47448Ralf, The charts put the grits together in order by grit or particle size which is just what you were trying to, with logic. There is a helpful Grit Comparison Chart for this Forum in the “Knowledge Base”, upper right.

This is what and how I try to use the stones. When staying within the same medium, by this I mean only Diamond stones, or only Ceramics, or only Diamond lapping films, or only strops, it makes perfect sense and is correct and practical to follow the progression from coarse grit or large particle size to smaller, finer grit and particle size. When you move from one abrasive medium to another it’s best to step back a grit size or two or up in a particle size to make a little over lap. Then again as you change mediums again in you progression, do the same thing and step back up a grit or particle size. This overlap makes for a better transition from medium to medium.

Each medium makes a particular scratch pattern. The scratch pattern becomes smaller and finer as you go down through the sharpening grit progression, with that medium. By taking the step back up a grit size or two when switching to the next medium it makes it easier to obliterate the scratch pattern left by the previous medium you used. As you go through the entire sharpening process, the purpose is to make these scratches finer and finer while you’re bringing the two bevel sides of the knife, together, to a finer more precise intersection at the apex or the knife’s edge. As the scratches are made finer and finer the edge appears shinier and almost mirror polished.

Remember my suggestions are based on broken in stones. Where you start, (i.e., how coarse a grit you begin with), is determine by how poor a condition the knife edge your sharpening is in and/or how much steel you’ll need to remove to sharpen it. From what you shared in your initial post I would start with the diamond stones 100/200 or 400/600, then follow this progression through the 1500 grit diamond stone. Then I’d use the ceramic stones, either the 1200/1600 or the 1.4µ/0.6µ, (my personal preference for the ceramics is the 1.4µ/0.6µ). Use only one ceramic pair or the other, I prefer not to use both ceramics. Then I’d finish with leather strops, 4µ/2µ.

This recommendation is strictly academic. You still need to follow it employing proper technique, for the right length of time, with the right amount of effort and with the proper degree of attention to detail to give you the results you seek. This all takes time, pratice and experience.

Marc

(MarcH's Rack-Its)4 users thanked author for this post.

08/23/2018 at 3:43 pm #47449Thank you. is there maybe a chart which can make it “logical” ?

Here’s a helpful discussion on our knowledge base: https://support.wickededgeusa.com/portal/kb/articles/sharpening-grit-progression-for-all-wicked-edge-abrasives

-Clay

5 users thanked author for this post.

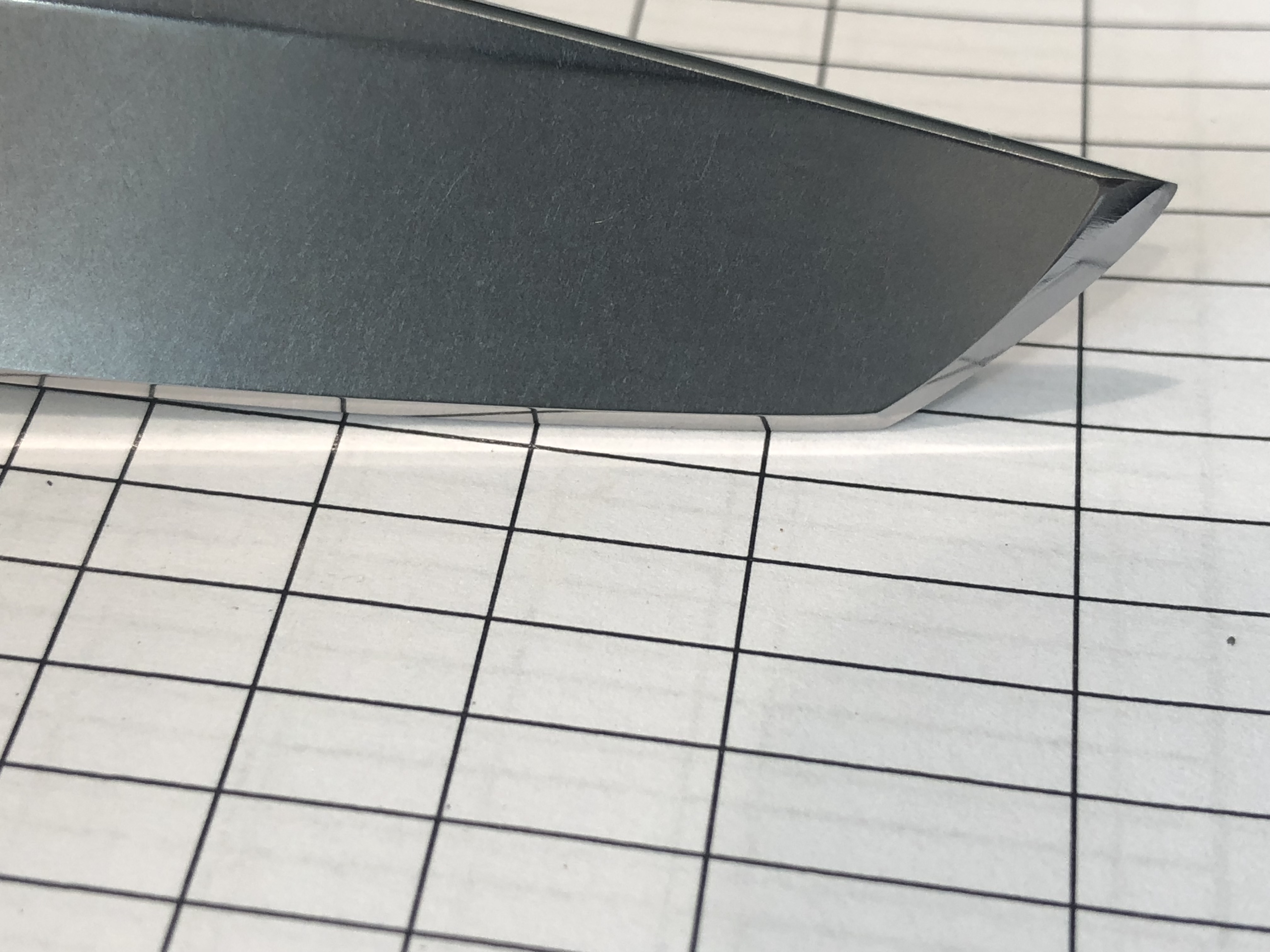

08/28/2018 at 12:43 am #47470I think I found a way for my sebenza, for softer steel I was not that happy 😆

400/600/800/1000/1500/micro fine ceramics rough side think 4micron it is/1200 ceramic/micro fine ceramic 0,5micron/1600 ceramic/leather with 1micron/leather 0,5micron

worked pretty good if I changed ceramics from logical way to “optical” matching

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.