Functional Difference in Strop Media

Recent › Forums › Main Forum › Stropping › Functional Difference in Strop Media

- This topic has 41 replies, 13 voices, and was last updated 12/30/2013 at 3:27 am by

Mark76.

-

AuthorPosts

-

05/29/2013 at 2:06 pm #11832

Why not PIE

The pie I saved for tonight.

Yum!

-Pie

12/17/2013 at 5:59 am #16027Hello Jacob and Samuel,

I just wanted to point something out. Burnishing is using a tool of a harder material to smooth the surface of a softer material. It is really caused whe the harder material applies enough force to overcome the yeild strenght of the softer material thus enabling a plastic flow of the softer material. This cannot really happen when rubbing hardened steel with leather. Leather would certainly not smear molecules of steel.

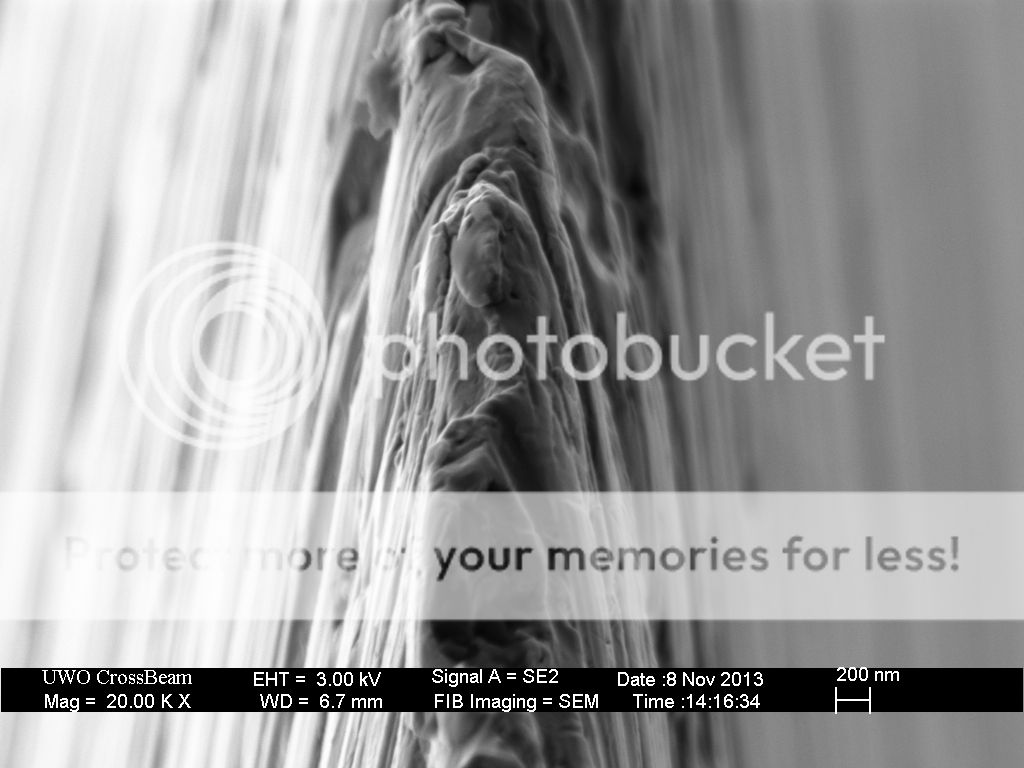

Leahther has abrasives in it that do affect steel, but you are abrading at a fine level and polishing…because of those abrasives. You are definitely refining the edge, but certainly not by burnishing.Straight razor edge, as honed.

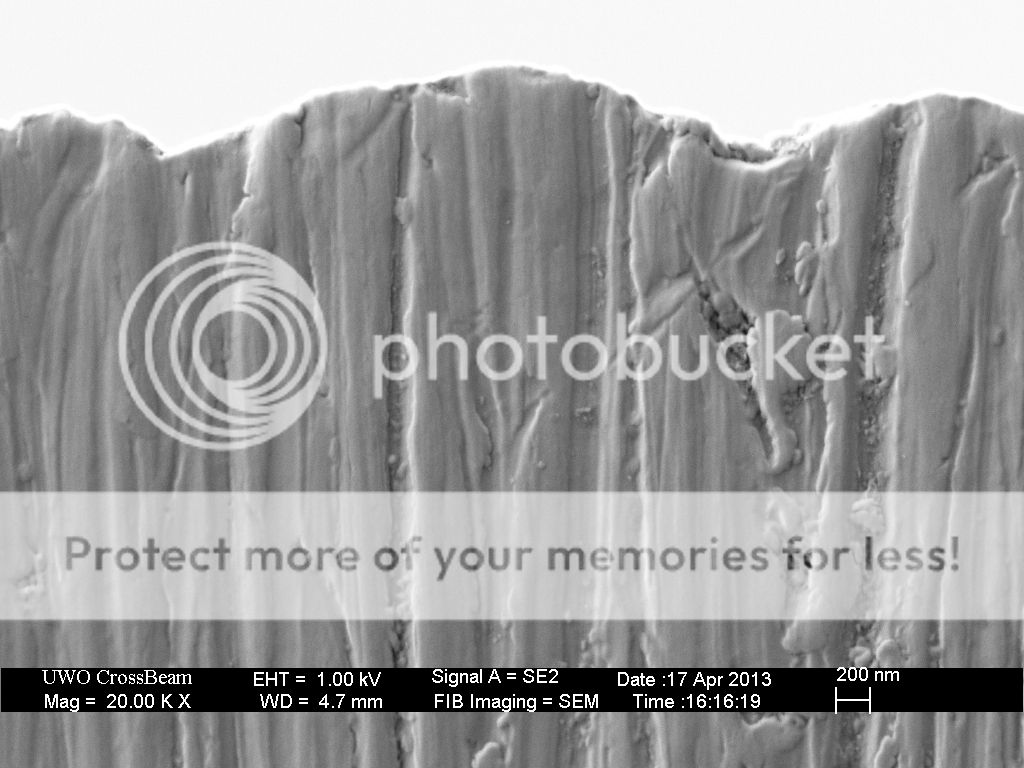

after 100 laps of stropping:

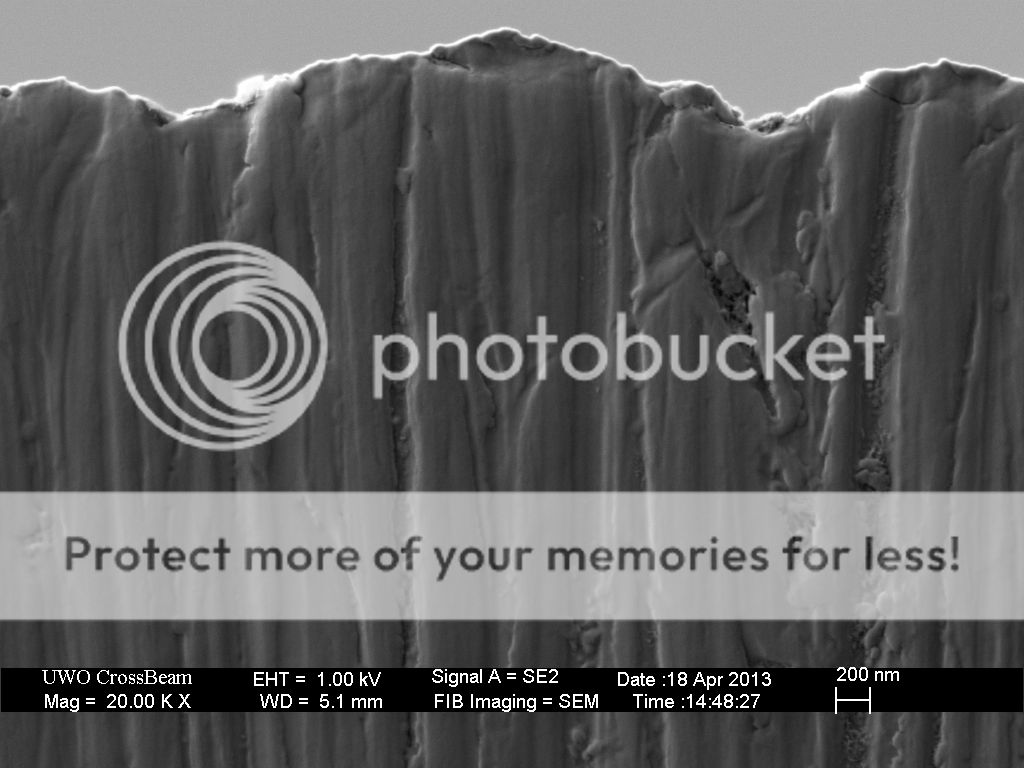

after another 100 laps of stropping:

Is this burnishing?

12/17/2013 at 1:59 pm #16030Nice pics! There have been heated discussions here about whether burnishing may occur during stropping or not. I can’t find them right now, but you could try to find them yourself using the search function (on the tab “Search”, not the search box).

I also wrote about this topic on my blog. See for example here[/url] and here[/url].

Success! And interested in your further findings!

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/18/2013 at 4:07 am #16033Nice pics! Where did you get them?

12/18/2013 at 5:13 am #16035Here is a stropping progression (on clean leather) in side view:

I have imaged the same location at each step.

12/18/2013 at 12:57 pm #16040Great pics! What microscope do you use?

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/18/2013 at 4:00 pm #16044Great pics! What microscope do you use?

Zeiss SEM

12/18/2013 at 6:00 pm #16045I take it the Zeiss is for your profession it seems that although fantastic for blade edges that level of both magnification & sharpness must be for some shall we say perhaps more serious use.

12/18/2013 at 6:05 pm #16046Great pics! What microscope do you use?

Zeiss SEM[/quote]

Man… Those are some fantastic pics

on the first ones, do you lower the stropping angle a couple of dps? I am curious as clay has shown and had success in showing that lowering the stropping angle increases the refinement of the edge vs keeping it at the same angle (which will round the very edge).

So are you up for some experimentation?

12/26/2013 at 1:33 pm #16171Nice pics! There have been heated discussions here about whether burnishing may occur during stropping or not. I can’t find them right now, but you could try to find them yourself using the search function (on the tab “Search”, not the search box)

I was part of most of the discussions. I don’t recall any HEAT at all. Maybe it is a matter of perception. I thought is was an academic exchange of thoughts..

I also wrote about this topic on my blog.

Not logic, or evidence that was accepted by all was presented there! Simply conjecture based on limited magnification photos showing you something that you had already decided was happening without sufficient data at hand

Success!(??) And interested in your further findings!

I too would be interested in controlled research with documentation via the SEM so that we might make some objective conclusions about what is happening to the steel.

Not sure what success in this context means. In looking at the…MOST excellent micrographs, I guess my interpretation differs a bit. At this small a scale, it looks like to me that the results could easily have been caused by polishing by abrasion. I can take sand paper on steel… 1000 grit FEPA.. on a macro level and see features that appear very close to what I am seeing in these SEM captures. Leather, plain leather having very small and very sparse abrasives… generally silicates, the plain leather strop could easily cause the type of wear patterns illustrated into the related micrographs, by polishing the material. This would hardly equate to causing plastic flow of the steel through rubbing it with with enough force as so as to cause plastic deformation of the steel.

Not sure, again, what success in this context means… If the steel is sharper, that is what I would call success. What “I” don’t’ see is evidence of burnishing, in the classical definition of that term!

“Burnishing is the plastic deformation of a surface due to sliding contact with another object. Visually, burnishing smears the texture of a rough surface and makes it shinier. Burnishing may occur on any sliding surface if the contact stress locally exceeds the yield strength of the material.”

Now, maybe someone can point out specifics in the photos that indicate that “plastic deformation” has occurred rather then (sub) microscopic wear patterns (abrasion). Perhaps it is there, but not needing to prove a point to myself that it IS… I just don’t see it. I have looked closely. I worked in a CAL/FAILURE lab for what was Martin Marietta Denver Aerospace, for 5 years, they, taught me to analyze wear patterns and identify the mechanism of wear that was causing different types of patterns in steel. I would have failed my certification class If I told them galling or burnishing was happening to metal as illustrated in the SEM captures . Being able to do this is was critical when performing failure analysis on parts and systems that are MAN rated. If I had deduced That wear was,caused by fine abrasion! That would have passed me… What we had to figure out was the amount and type of wear that occurred in metal parts that rub against east other, and as completely understand the mechanism of the wear, and precisely predict wear over time. There could be no errors or personal bias involved. It was the potential for losing men’s lives in flight that forced us to do it correctly.

Again, I really have no clue what why mark wrote “success” when he did that.

Interesting… after all of these months… and lots more questions than real answers.

We proclaimed success Still unclear about what succeeded and what is the proof of that.

Maybe one day we can discuss biases in observing… it is part of the human psyche. We mostly see what our brains tell us we want to see.. it is inescapable!

Merry Christmas ALL and the best of New Years as well!!

Glad to be back for awhile!

Though I am feeling no heat whatsoever…!! Hopefully I am not emitting any eitherIf what seems to be called heated here is related or correlated to global warming… the glaciers will be in fine shape for many thousands of years!! :cheer:

But glad to be able to exchange ideas with you folks in any case, at least for the moment!!!

Phil

12/26/2013 at 10:38 pm #16179To keep things simple in my mind, sometime I am guilty of over-simplified. After spent a bit of time looked at these SEM pics. One can agree that burnishes occurred either during sharpening and or stropping. If a medium/steel capable of having stable stretched & elongated & (idk but plausible) displacement volume, then this behavior COULD taken place at nano stropping level. unless the medium consists of discrete grain/block where impact from stropping never exceeded yield strength. Let’s call this extrapolated deduction :dry:

12/30/2013 at 3:27 am #16222

12/30/2013 at 3:27 am #16222I agree Bluntcut. I don’t know exactly what caused it (burnishing is a verb, not a noun), but the spot you mark has definitely gotten bigger. That’s not a phenomenon we usually see after wear.

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.