Angle Cube Question

Recent › Forums › Main Forum › Angle Cube Question

- This topic has 26 replies, 7 voices, and was last updated 02/11/2018 at 9:30 am by

Marc H.

Marc H.

-

AuthorPosts

-

11/22/2017 at 11:44 am #42232

When using the angle cube do I need to keep it perfectly vertical (like referenced to a plumb bob) in order to get the correct angle ? If so, how do I do that easily ? If not, which position gives the correct answer since the answer changes depending on the cube’s verticalness.

11/22/2017 at 12:39 pm #42233I can’t say for sure that it’s true for all of them, but in general, yes. Your plumb-bob example is a good one, since many/most of these inclinometers use MEMS (micro electro mechanical systems) accelerometers as the sensor, and these have varying outputs that are proportional to how much you deviate from the direction of gravity. About all you can do (unless you want to buy a 2-axis inclinometer) is eyeball it. Or maybe attaching a 12″ ruler to the back face of the cube would make it easier to judge that your’re keeping the imaginary plane through the middle of the cube straight up and down.

I think people tend to put way too much trust in these cubes. You also cannot trust that the side are at exactly 90* regardless of what it reads, or that the top and bottom are perfectly parallel. But they are often used as if the cube is a precision square, and the only error is the +/- .2 degrees that most of the cheaper ones claim as their accuracy.

Edit: Here’s some more info: https://www.digikey.com/en/articles/techzone/2012/jul/a-designers-guide-to-mems-sensors

and a relevant passage: “Although it may seem counterintuitive, an accelerometer can sense the inclination (tilt) of a device – even when stationary. Since gravity is an acceleration of 1 g, tilt is proportional to the sine of the angle the accelerometer makes with the Earth’s gravitational field.”

3 users thanked author for this post.

11/22/2017 at 1:06 pm #42237Hope this helps, from the knowledge base

<h3 id=”using-the-digital-angle-gauge”><span id=”Using_the_Digital_Angle_Gauge” class=”mw-headline”>Using the Digital Angle Gauge</span></h3>

An angle cube allows one to set the angle EXACTLY.Here’s how:

- Set your knife in the sharpener and decide the angle (ie. 18 per side.)

- Put the angle cube on the base of the sharpener and zero it.

- Put the stone on the sharpening rod and set the pre-marked scale to 18 degrees.

- Lay the stone against the knife as if you were going to start sharpening

- Put the Angle Cube on the side of the sharpening stone that is not against the knife…..

- READ THE ANGLE. It probably will NOT be 18 (due to inherent differences in the height of each knife being sharpened.)

- Adjust the angle until it reads 18 on the Angle Cube

You now have a true 18 degrees.

(Posted by R.JeffreyCoates in the forum.)

2 users thanked author for this post.

11/22/2017 at 1:50 pm #42245When using the angle cube do I need to keep it perfectly vertical (like referenced to a plumb bob) in order to get the correct angle ? If so, how do I do that easily ? If not, which position gives the correct answer since the answer changes depending on the cube’s verticalness.

If you’re using the iGauging Angle Cube, then yes, it needs to be plumb to be accurate. My DXL360S doesn’t seem to require being plumb.

-Clay

4 users thanked author for this post.

11/22/2017 at 1:58 pm #42246Redheads for me consistency in the way I take the reading and doing it in a easy repeatable manner is more important than whether the angle cube is perfectly vertical. I lay the stone as close to centered with the vice jaws as I can judge so the stone with the attached angle cube rests on the flat bevel without rocking, and try to replicate this same position on the opposite side. (If I’m using a whetstone I have to hold the meter against the stone). This is my general rule and is easy to replicate it with any knife or the same knife when resharpened. For me consistent repeatability is more important than absolute precise accuracy. After all the angles are all relative anyway.

If you take your reading and move the stone with the attached angle cube forward toward you or away form you and observe the readings I find that it stays pretty close to the same reading for me as long as I’m not too far forward or too far back where it’s visually obvious I’m way off vertical.

I do use a dual axis Angle Device that probably would show when I’m off vertical if I used it in that manner.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

11/22/2017 at 7:35 pm #42252I understand, however, when I reach the tip (which is at the end of a curve on pretty much all knives) it is nice to know what angle I am putting there. It seems kinda of silly to use a $40 inclinometer accurate to 0.2 deg when plump and then use your eye to indicate plumb. I know relative et al. but if I am determining somewhat accurate angles (over the entire blade length) it is counter intuitive to depend on my eye. I am dealing with kitchen knives which are inherently longer that folding knives, some are 10-12 inches long and the angles over the full length are important to me. I would expect WEPS to be transparent in the limitations and options available especially if dual axis DXL360S is priced at:

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

11/23/2017 at 7:56 am #42259Redheads- this is a fixed angle sharpening device. The bevel angle remains the same set relative angle all along the blade as you sharpen from heel to tip. This was proven to a nay sayer on You Tube not to long back. I’m hoping someone will fill that link for you soon.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

11/23/2017 at 9:19 am #42261Redheads, Here’s one youtube video showing the angle remains the same, and here the other one where he discovered he was wrong then his results where he realizes he’s wrong , the angle doesn’t change.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

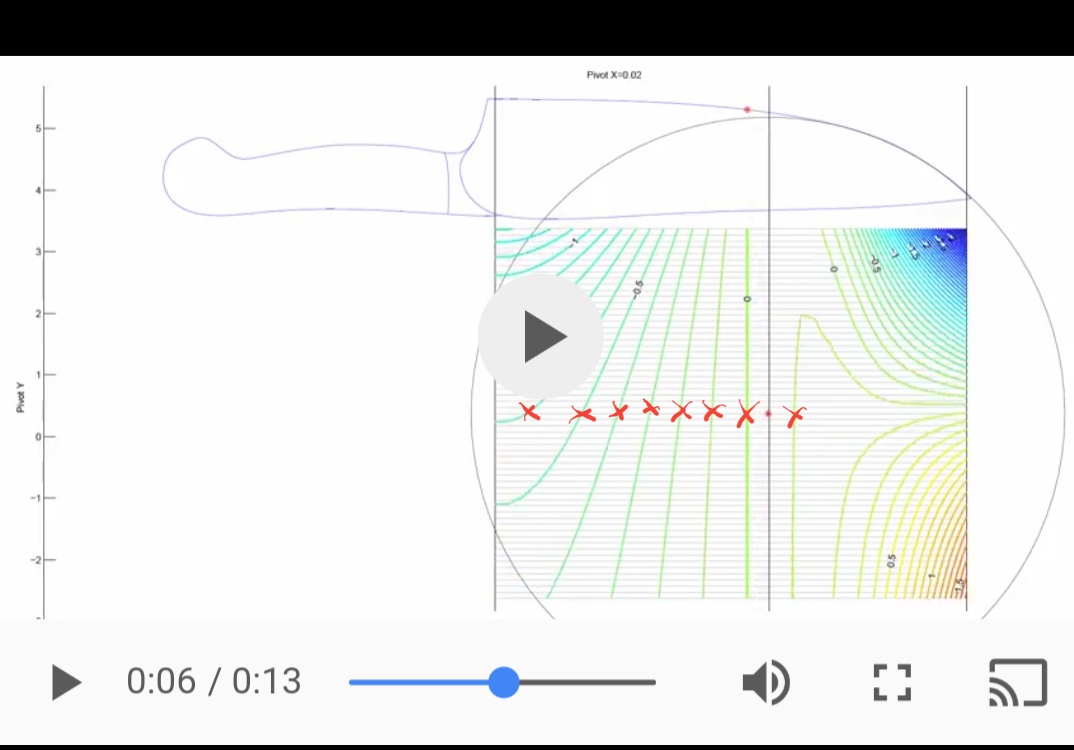

11/23/2017 at 11:45 am #42262I am aware and have read thru Anthony Yan’s great analysis and am in full agreement. However, he also points out that very few knives are perfectly “flat” and the curves to the tip must be in the same pivot point radius length for the angle to remain the same. His document has really cool animations (link below). I parsed out a piece of it also. It is very cool and appropriate for kitchen knives. Verification via the angle cube requires plumbing (sic) or I suppose a two axis inclinometer.

Geometry-and-Kinematics-of-Guided-Rod-Sharpening-Systems-Example

https://photos.app.goo.gl/L8ANqvuCgO8MCrG22Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

11/25/2017 at 3:19 pm #42269Most of my better knives are handmade. I believe the precision Redheads is suggesting he’s striving for is possible on paper and theoretical. In reality it’s more precise than the knifesmiths have forged these handmade knives.

IMO, it’s doesn’t make for a sharper knife knowing I applied an angle, including at the curve to the tip, with 0º angle deviation from a perfect angle setting. My 15º ±0.02º, or ±0.06º, or ±0.09º, whatever it ends up being, will cut just as well and look just as nice as the 15.0º±0.00º beveled edge. Only the knife sharpener knows or cares. The only thing to gain with the more true angle is bragging rights and a lot more effort and work.

I think this subject makes for some fun, interesting and, stimulating discussion but in practice it’s far from reality, unnecessary and impractical.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

11/25/2017 at 4:52 pm #42270MarcH, While this surely borders on the theoretical there are also some practical applications related to the initial positioning of the kitchen knife (which will then be used in the future for all tune ups and redo’s). Depending upon the initial knife position indicated by moving vertical line in the movie (and pausing it where you want the position to be), there will be an angle variation of up to 3-4+ degs over the length of the blade. This is an order of magnitude greater than what you mentioned. To me it is very important when determining the initial position. I also have no desire to do dual position sharpening. Before knowing any of this, I sharpened a 12 inch slicer with flex which gave me an inconsistent (due to flex) much smaller angle (due to drift for lack of a better word) at the tip. I was not happy and it drove some of my other posts about holding a flex blade rigid. WEPS requires a stiff blade otherwise why would we go thru all this trouble and cost if flex is the largest error source.

All this rambling points back to my use of the single axis angle cube to verify what the angle will be. I suppose I should get a dual axis so my eye doesn’t have to be an error source.

Note that I only sharpen my own kitchen knives plus a few others for relatives.

Anyway, Happy Thanksgiving !

11/25/2017 at 5:53 pm #42271This model is less expensive than the model you included in your post above if that’s of any consequence, that is if you can tolerate double the inaccuracy in the less expensive model compared to the more expensive one, (±0.1° VS of ±0.05º) and double the resolution, (0.02° VS of 0.01º). For me these numbers are academic since I can’t function at this level of precision. After all the WEPS is still just a hand tool, not a precision automated machine.

Am I missing something but isn’t the positioning of the knife independent of the limitations of the WEPS? The limitations are what they are and these don’t change. In order for you to use the WEPS to it’s best ability it’s up to you, the user, to learn how to position your knife so as to gain the best repeatable results you can. A tool such as the Dual Axis Inclinometer, (fancy way to say Angle Cube), doesn’t help you to clamp your knife in the proper position to gain the best repeatable results you seek. Or am I missing something in this discussion?

And a Happy Turkey Day to all also.

Marc

(MarcH's Rack-Its)11/25/2017 at 8:36 pm #42272If you’re using the iGauging Angle Cube, then yes, it needs to be plumb to be accurate. My DXL360S doesn’t seem to require being plumb.

Interesting. The Amazon product description for the 360S notes this:

“…any angle measurement, measure the angle between two faces, not only in earth gravity direction“

11/26/2017 at 8:27 pm #42296His document has really cool animations (link below). I parsed out a piece of it also.

Is this a technical way of the “finding the sweet spot” thing? Even after watching the vid, I don’t think I get it. Maybe someone could explain the x and y axes, as they relate to WE. I’m assuming x is front to back. Are we saying the y is the vertical axis? If so, then the higher up the rod we go, the angle changes there?

11/26/2017 at 9:29 pm #42297It is a tech way to find the sweet spot for “the specific knife in the video”. However, that specific knife is only used to demo the results of the math (verified by many with plumb angle cubes) as the WEPS handles traverse over the full length of the blade.

You are correct that x is the length of the blade and y is the height of the blade. It has been shown thru math, plumb angle cubes and ad hoc youtube vids that the WEPS angle does not change over the length of the blade under 2 conditions: 1. Straight sections like those on a razor (which most knives don’t have much of) and 2. Curved sections of a constant radius (again which most knives don’t have much of).

WEPS is great at repeatability (assuming the knife doesn’t move) but predicting the angle delta you will get in x positions other than the initial set handle position are challenging. The sharpie trick is nice and the angle cube is nice (but it must be plumb). It is the geometry of the knife and how y changes with respect to x which dictate how the angle changes. It will change but by how much is the question. Many here (including me) say it really doesn’t matter as long as it is repeatable and consistent when resharpening . This is what drove the need for the alignment guide. However, if you don’t think it through upfront during first time usage of WEPS on a 10 inch slicer, you can end up with 15 dps on the mostly straight section and 10 dps at the tip. Sometimes this is desired, sometimes not.

Anyway, to end my rambling, if you stop the video where the center red dot is (pic), meaning that for this case that is the location of the spherical joint, then you can visually project the red dot to the right or left and note how many colored lines it crosses. I put red x’s on the pic to show. If you go to the right there is only one colored line to cross (this correlates to the small distance from the red dot on the knife edge where the initial WEPS angle was chosen to the start of the perfect circle to the tip). The angle along this perfect circle will not change. If you go to the left there are seven red x’s which each account for 0.1 deg for a total of 0.7 deg change. Not much but it is good to understand. This is also pretty close to a minimum and as knife geometry varies from this then the deviations are greater.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.