Advantages and disadvantages of different sharpening techniques

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advantages and disadvantages of different sharpening techniques

- This topic has 63 replies, 9 voices, and was last updated 11/20/2018 at 12:14 pm by

wickededge.

wickededge.

-

AuthorPosts

-

10/06/2017 at 12:03 pm #41422

TC you bring up something I’ve been wondering about. Many knives I come across have those pesky little chips. As we remove them by taking off quite a bit of steel (relatively speaking) we start going into thicker parts of the blade which long term will require thinning of the blade. Is it possible to do thinning with the WEPS ?

10/06/2017 at 1:20 pm #41424I was doing a bit of reading of Roman Landes work (German) on the effects of sharpening on fine edges (our domain). He gets into the heat and stress applied to an edge during grinding and the importance of a wet setup. This is very relevant to belt grinding and I wonder what effects are happening while using WEPS which may impact edge retention.

He talks about excess heat at the micro scale which is both unobservable and unmeasureable but certainly exists. It would be interesting to run some edge retention tests after using the WEPS upside down while the knife is immersed in a bucket of water – LOL.

1 user thanked author for this post.

10/06/2017 at 1:55 pm #41425TC you bring up something I’ve been wondering about. Many knives I come across have those pesky little chips. As we remove them by taking off quite a bit of steel (relatively speaking) we start going into thicker parts of the blade which long term will require thinning of the blade. Is it possible to do thinning with the WEPS ?

I have thinned the profile of several knives, that is the shoulder behind/above the edge and higher, still, above the shoulder. Some issued I ran into: 1) it’s hard to achieve an angle that low with the WE System, without hitting the jaws and/or vice. 2) It’s a lot of steel to try to remove by a method intended to remove small amounts of steel. (Especially if it’s a very hard steel). 3) It’s hard to remove that amount of steel and maintain the smooth, consistent and uniform shape of the knife’s original grind. My impression, to truly thin the grind of a knife is a regrind requiring the use of a proper tool like a belt grinder or a long slow process by free hand on a large flat stone.

The next best thing I found was to profile the knife to as narrow a bevel angle as I could accomplish with the WE and that edge width could support, then apply another bevel, micro bevel, on top at a wider angle for longevity and durability. This gave decent results if the blade width at the shoulder wasn’t too wide. It added usefulness back to a worn wide knife and prolonged the need to regrind. IMO, to really regrind a knife it has to be an expensive, fine knife, worth the investment and requires a talented experienced individual to do it correctly and not destroy the knife or ruin the steel. You may end up spending as much on a regrind as the original knife cost, or more!

Marc

(MarcH's Rack-Its)10/06/2017 at 1:59 pm #41426I was doing a bit of reading of Roman Landes work (German) on the effects of sharpening on fine edges (our domain). He gets into the heat and stress applied to an edge during grinding and the importance of a wet setup. This is very relevant to belt grinding and I wonder what effects are happening while using WEPS which may impact edge retention. He talks about excess heat at the micro scale which is both unobservable and unmeasureable but certainly exists. It would be interesting to run some edge retention tests after using the WEPS upside down while the knife is immersed in a bucket of water – LOL.

Maybe use Shaptons or Choseras Whetsones made for the Wicked Edge

Marc

(MarcH's Rack-Its)10/06/2017 at 2:53 pm #41427He talks about excess heat at the micro scale which is both unobservable and unmeasureable but certainly exists.

I’ve read this opinion on the web a few times, including some impressive claims of very high heat at the local level. I have also seen it refuted vigorously. Parts of the argument on both sides made some sense. To it, I’d add that it’s possible that the work-hardening that is claimed to happen at the very edge would need to be considered as well if someone is claiming that the localized heat is changing the heat treating and temper i.e. is the alleged annealing countered by the alleged work-hardening?

To make sense of it, I guess the first thing we should ask is if our knives are behaving as though they were annealed. To most easily test it, we should take a hardened, sharpened blade and anneal it to see how it performs. Ideally, we’d have two identical blades from the same batch and we’d sharpen both, anneal one and then test them for edge retention.

-Clay

10/06/2017 at 2:56 pm #41428I wonder if it is possible to some sort of Rockwell Hardness test on the edge

10/06/2017 at 4:05 pm #41430It would be interesting to run some edge retention tests after using the WEPS upside down while the knife is immersed in a bucket of water – LOL.

That’s a creative idea right there. I never would have thought of that.

He talks about excess heat at the micro scale which is both unobservable and unmeasureable but certainly exists.

I’ve read this opinion on the web a few times, including some impressive claims of very high heat at the local level. I have also seen it refuted vigorously. Parts of the argument on both sides made some sense. To it, I’d add that it’s possible that the work-hardening that is claimed to happen at the very edge would need to be considered as well if someone is claiming that the localized heat is changing the heat treating and temper i.e. is the alleged annealing countered by the alleged work-hardening? To make sense of it, I guess the first thing we should ask is if our knives are behaving as though they were annealed. To most easily test it, we should take a hardened, sharpened blade and anneal it to see how it performs. Ideally, we’d have two identical blades from the same batch and we’d sharpen both, anneal one and then test them for edge retention.

I’m not a physicist or engineer, but I find it pretty hard to believe that a manual sharpening process on the Wicked Edge really generates enough thermal energy to ruin the heat treatment of the edge. The heat capacity of the steel at the edge is relatively small (meaning that it only takes a bit of energy to generate a relatively large change in temperature) but that also means that it only takes a small amount of cooling to dissipate that energy and keep the steel near room temperature.

10/06/2017 at 4:23 pm #41431I wonder if a local temp could be measured with one of those infrared temp meters. Is there a difference between “over scrubbing” vs. alternate long pass techniques. It interests me because there is no getting away from physics and accurate answers as to why blade edges sometimes chip and sometimes don’t are elusive. I keep thinking of the paper clip band demos.

Of course, I may be over thinking it all together but there are people way smarter than me who consider these effects. Roman Landes supposedly participates on the hypefreeblades forum and I will see if I can engage him. Failure mechanisms are fascinating. it brought down the shuttle and stopped the SSTO program.

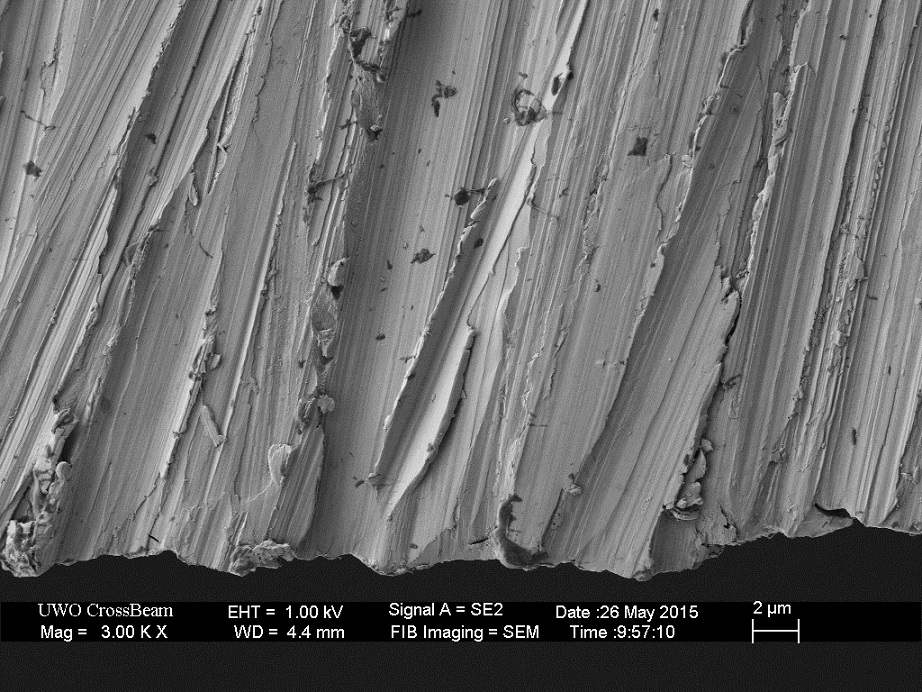

10/06/2017 at 4:50 pm #41433In looking through hypefreeblades I came across this great photo (with more in the link) and just had to share.

http://www.hypefreeblades.com/forum/viewtopic.php?f=4&t=849&start=10

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

10/06/2017 at 4:54 pm #41435I love SEM images of blades. They really show the plasticity of steel.

-Clay

10/06/2017 at 5:17 pm #41436Don’t get me wrong…all this theoretical physics of knife sharpening is interesting and makes for fun conversation, but why would you ever even worry about this stuff? Sorry if I’m being an idiot. It’s way beyond the scope of the Wicked Edge Forum helping Wicked Edge users to sharpen knives with their WE Systems. Especially if your knives are taking and holding a sharp edge using the Wicked Edge System. Why would ever think about this stuff? If I had a problem with a knife I sharpened, first thing I’d consider was my technique or how I handled the knife. Then after that and a hole long list of other things, I can’t imagine ever thinking I overheated the edge on a sub-microscopic level to cause edge failure??? Sorry… there’s too many other cool things that actually impact my sharpening experience to consider.

I do love SEM photos, though!

Marc

(MarcH's Rack-Its)10/06/2017 at 5:32 pm #41437Well, I am an engineer and have been chasing these kinds of things for 30 years. On a specific WEPS question, I just got a new Kramer Essential AEB-L with double cryo, I sharpened it out of the box on WEPS, real nice edge, used it twice in the kitchen (nothing crazy), put it back on the WEPS to do some bevel thinning and found a small chip. Pissed me off. I use a 250x USB scope. I left the chip instead of doing all the steel removal but it reinvigorated my desire to try and figure it out. Its the same reason I get pleasure in growing better tomatoes in my garden.

1 user thanked author for this post.

10/06/2017 at 5:49 pm #41438That gives me a little more insight in your drive. (I also have some Kramer Essentials in FC61, [his VG10], very nice knives and very sharp). You failed to share how you sharpened your Kramer Essential on your WEPS. Those kind of details help others to help you solve your issue and helps others who read the forum to learn from your experiences. Wouldn’t you look for a possible solution here first before you jump to theoretical physics and a failure in the double cryo phase of the heat treatment? Certainly a practical solution you can use to overcome an issue like this in the future would maybe be more helpful to you an others then a discussion on a theoretic level that has little bearing other than it’s intellectually stimulating, oh, and fun for you?

Marc

(MarcH's Rack-Its)10/06/2017 at 7:18 pm #41439I am not sure how to respond without getting into an argument but I will try. I am not asking for a solution, I am only looking for discussion which is what forums are for. I am not sure why you keep asking why I am interested in the variations which may affect the long term viability of kitchen knife edges. The WEPS techniques are pretty straight forward and I have done probably 100 sessions in plenty of scenarios. I suppose the WEPS forum is the wrong place for this. As the moderator maybe you can tell me what this forum is for.

BTW, as far as I know FC61 is not VG10, it is AEB-L. FC is Fine Carbide and 61 is RHC.

10/06/2017 at 7:18 pm #41440Well, I am an engineer and have been chasing these kinds of things for 30 years. On a specific WEPS question, I just got a new Kramer Essential AEB-L with double cryo, I sharpened it out of the box on WEPS, real nice edge, used it twice in the kitchen (nothing crazy), put it back on the WEPS to do some bevel thinning and found a small chip. Pissed me off. I use a 250x USB scope. I left the chip instead of doing all the steel removal but it reinvigorated my desire to try and figure it out. Its the same reason I get pleasure in growing better tomatoes in my garden.

Man, that’s a bummer. What kind of cutting board are you working on? Some of the plastic boards can be very rough on knife edges.

-

AuthorPosts

- You must be logged in to reply to this topic.