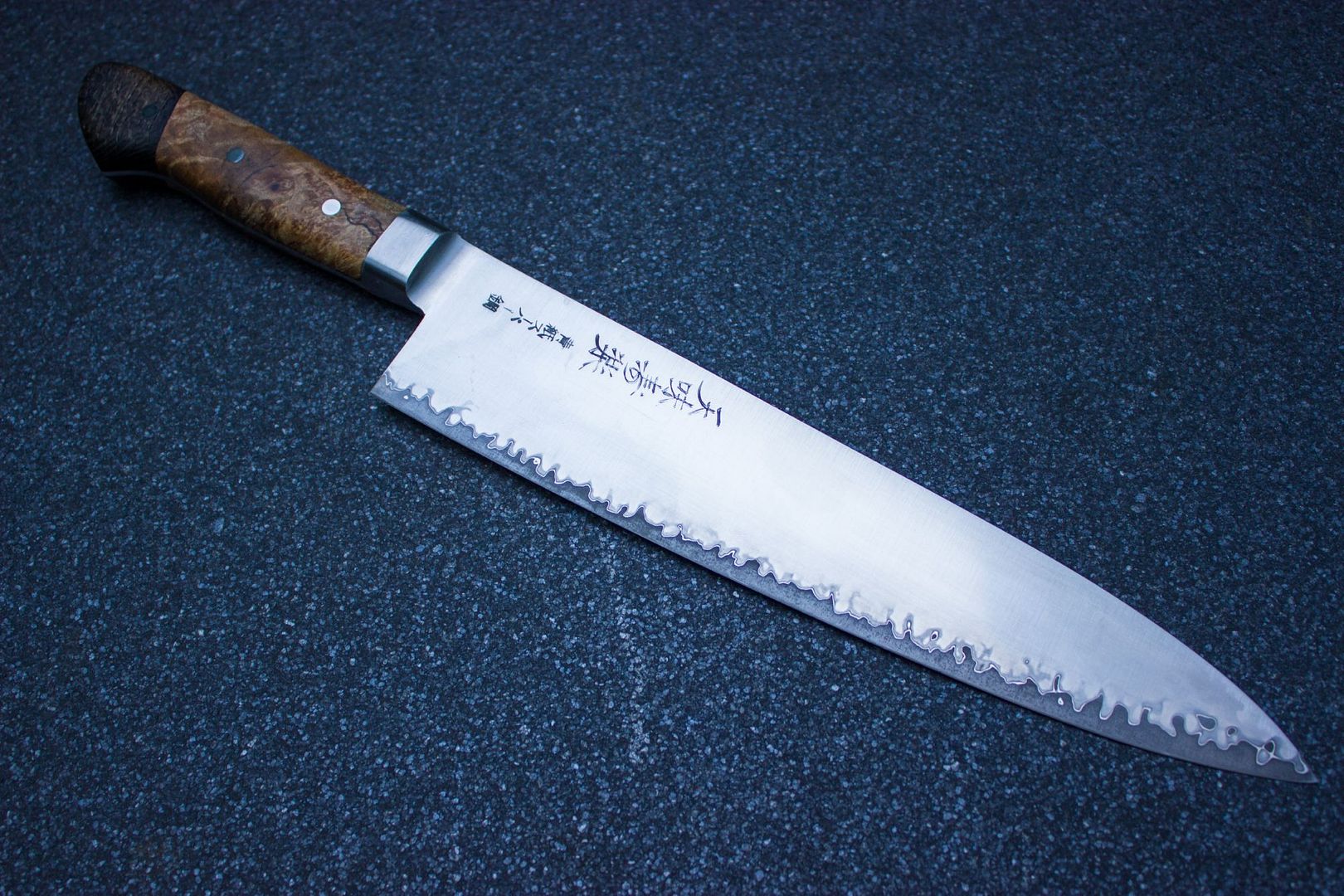

Hiromoto 240 mm AS gyuto

Recent › Forums › Main Forum › Off Topic › Hiromoto 240 mm AS gyuto

- This topic has 0 replies, 1 voice, and was last updated 07/11/2015 at 5:14 pm by

Mark76.

-

AuthorPosts

-

07/11/2015 at 5:14 pm #25977

When I first got into Japanese kitchen knives, the Hiromoto AS (Aogami Supersteel) gyuto was hard to ignore. A lot was written about it on forums and it was generally described as a great introduction to Japanese kitchen knives. The knife was not described as flawless: I read reports about a handle that did not fit well and the knife was reportedly a bit thick behind the edge. Nevertheless it was one of the cheapest knives sporting Aogami Supersteel.

Only about a year ago I decided to get one. One of the reasons is that this knife will cease to be made. The owner of Hiromoto company will retire soon and he does not have a successor. And the knife appeared to be even more of a classic than I had realized. It had actually made it into the http://www.wsj.com/articles/SB10001424053111904716604576546621007499618%5DWall">, where it was described as a “timeless treasure”.

First impression

When I received the knife, I was pleasantly surprised. The fit and finish of the knife was more than ok. The handle fit the knife well and the bolster made a nice transition from the handle to the blade. There were no gaps or even rough spots at all. The spine of the blade had not been rounded, but chamfered a bit. The choil had not been chamfered, but there were no sharp edges.

The blade grind was another surprise. The knife was thinner behind the edge than I had expected based on the reports I had read. The knife also had an interesting geometry. It was pretty asymmetrical: nearly straight and flat on one side and steep, like in a full flat grind, on the other.

In practice this worked out well. When I tried the knife on some veggies, it hardly wedged. Only on vegetables like winter carrots and white winter radish I could notice some wedging.

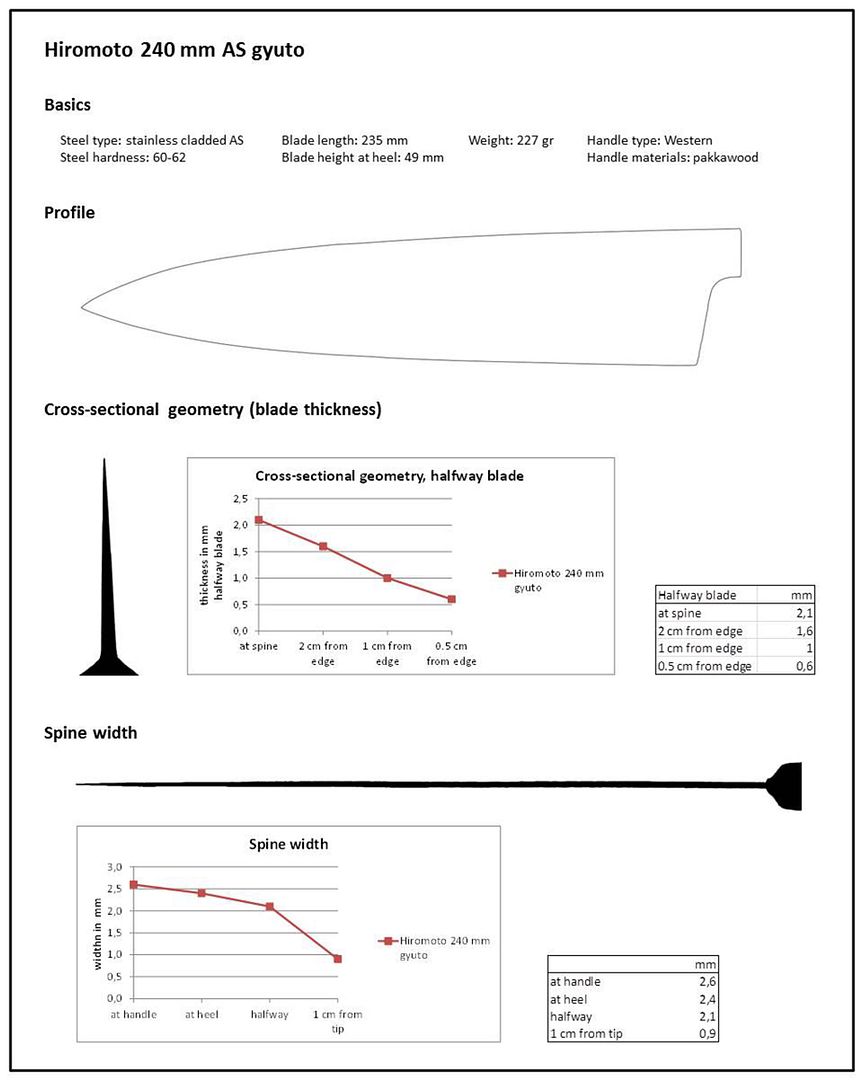

The knife was also thinner than I had expected. Its spine is 2.6 mm wide above the heel. The spine tapers only a little bit until a couple of centimeters before the tip, but then it tapers down to 0.9 mm one centimeter from the tip. This isn’t the thinnest tip I’ve seen, but it works ok for the finer work.

The knife looked a bit bland with its black pakkawood Western handle and its hardly noticeable transition from the jigane (the soft stainless cladding) to the hagane (the core AS). But I got this knife for its steel and its performance, didn’t I? Well…

Dave Martell has popularized the “spa treatment” for Hiromoto knives. Dave’s spa treatment involves thinning the blade and then etching it, so the distinction between the jigane and the hagane becomes more prominent. And it involves a rehandling of the knife. The spa treatment to my Hiromoto was given by Tim Johnson of Blackstone Knife and Tool.

Second impression

My second impression was one of horror. My second impression was one of horror. The knife had been shipped. This is the result of the USPS treatment.

Thanks to a nice US kitchen knife dealer the knife was completely straightened again and this is the knife when I received it back.

The new handle is made of maple burl and black painted Hawaiian silky oak. A nice thing is that even after the rehandling the balance point is about 2 centimeters in front of the bolster.

After thinning the knife cut even better than before. Sometimes people say their knife “falls through” food. I now know what they mean. The weight of this knife (227 grams) certainly helps.

An important reason for getting this knife was that it has a core of Aogami Supersteel. Over the past years I’ve used knives made of many different types of steel: various types of stainless, semi-stainless and carbon steel. But if there is one steel that is the best in terms of both taking and holding an extremely polished edge, it’s Aogami Supersteel. And Hiromoto got their heat treatment of this steel right.

I sharpened the knife with my Shapton Pro stones up to 30K. Normally these 30K stones are for straight razors only. On many kitchen knives I do not notice any improvement anymore after 8K and I seldom notice any improvement after 15K. But I did on my Hiromoto knife and I continued stropping with 0.25 micron and 0.1 micron diamond sprays. The Hiromoto was now definitely the sharpest knife I’d ever felt. It just needed to touch a tomato to split the skin. Who wants a toothy edge when you can get it this sharp?

Needless to say that the Hiromoto easily dealt with everything I threw at it: hard veggies, soft veggies, proteins. Only with stuff that required delicate tip work it was not optimal due to its tip that is slightly thicker than on some other knives.

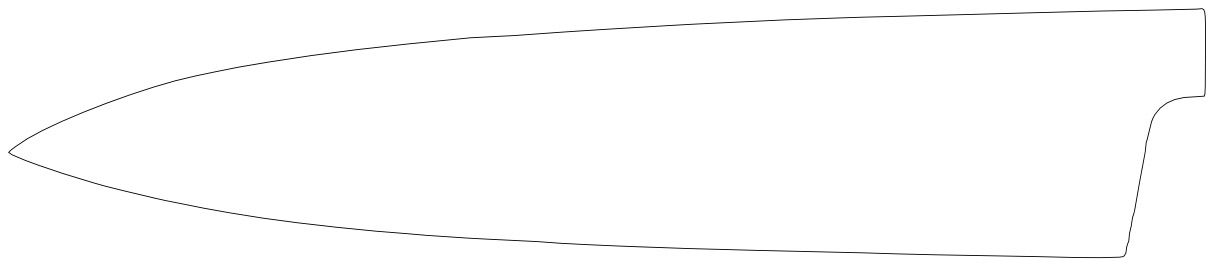

I also like the profile of the Hiromoto, which I’d describe as all-round. It has a nice flat spot at the heel, but also sufficient belly for rock chopping.

Food release is not great on this knife, as is the case with most other thin knives.

Conclusion

The Hiromoto AS gyuto is not just one of the cheapest knives sporting Aogami Supersteel. It is a well-made knife with a good fit and finish that cuts fine. And if you decide to give it the spa treatment, you’ve got a knife that is a great looker and cuts very well. They are not made anymore and due to their popularity they are even hard to get second-hand. But if you can lay your hands on it, I highly recommend it.

Factsheet

Click on the factsheet for a larger version.

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.