Steak Knife Touch Up Issue

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Steak Knife Touch Up Issue

- This topic has 28 replies, 9 voices, and was last updated 09/02/2017 at 11:09 pm by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

08/16/2017 at 11:05 am #40633

I’ve been using WEPS Field and Sport Pro for a couple of years now and have grown my set to include Alum Oxide films and emulsions. I am able to put very sharp edges on all my knives which I measure by the ability to do slice cuts through lightly folded bends of single phone book pages (the only use for a phone book for me anymore). I do find that my carbon edges (Shun Blue) come out the sharpest.

The issue I have is with my non-serrated Henckel 4 star steak knives. I have 8 of them and we use them every day while eating. I know that using them on dinner plates damages the edge but I do not care since they are a pleasure to use. I use a ceramic hone (~1000 grit) to ever so gently (3-4 times per alternate side) straighten the edge every few days. Of course this is done free hand. I scrape my thumb nail to know when the edge is straightened. I can tell which side needs straightening during the process by tilting the knife during the thumb scraping motion.

I say all of this because WEPS touch up has become an issue. I use the alignment guide religiously by putting the tip in dead center of the documented square and making sure any slop biases are in the same direction. I use the angle cube, sharpie and 250x USB scope to verify I reach my 20 DPS apex. I have done all 8 knives about a half dozen times. Even though I go thru all these setup steps (doesn’t take too long), I have always gone to the lowest grit needed to quickly raise and verify a full burr (usually 400 grit). I finish them with the 1500 grit (which I love). However, the last time I did the full set of 8, I was time constrained and did not want to spend 10-15 mins per knife. I wanted to spend 5 minutes to touch up each knife (ie. don’t take the time to raise a full burr) since I figured I shouldn’t have to based on my consistent setup to previous sharpening efforts. I did the first knife (800,1000,1500 grit) and it felt nice and sharp in the clamp but when I removed it from the clamp it failed my phone book test. I chalked it up to an anomaly but the next 3 knives had the same issue. My stubbornness took over and I ignored my time constraint. For the next 4 knives (exact same setup) I went down to the 400 grit, raised the burr and went thru (600,800,1000,1500). They all passed my phone book test.

Observations:

- When observing the knife (post sharpie and first pass of the 800 grit), I can somewhat clearly see that I have reached the apex, but after I go through the “touch up” progression (800,1000,1500 & no burr verification) and compare the knives to the (400,600.800,1000,1500 grit & full burr verification) knives, the “touch up” knives lose every time.

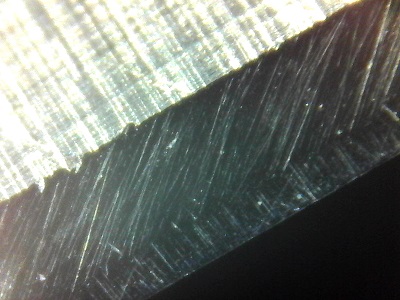

- When observing the knife (pre-sharpie) under 250x, I can clearly see the scratch pattern that my 1000 grit ceramic hone put on the blade. The 1000 grit scratch pattern is only on the top 20% of the bevel. Obviously, I am not holding the 20 DPS angle on the ceramic hone and am removing metal which then messes up my WEPS touch up process.

Questions:

- Should I stop using my ceramic hone ? Maybe go to smooth steel hone ? I got rid of my grooved steel hone cause I see it rip up the edge under 250x.

- Does anyone have a quick touch up method/hone which will preserve my bevel so when I pull out my WEPS for touchup I do not have to raise a full burr ?

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

08/16/2017 at 11:39 am #40635If you see the ceramic stone is scratching the bevel in the top part of the bevel then it’s like applying a micro-bevel. That may help the edge longevity and durability. Have tried using a leather paddle hand strop for touchups? I get great results touching up my kitchen knives with the strop in between sharpenings.

Marc

(MarcH's Rack-Its)08/16/2017 at 11:54 am #40636Will the strop act as an edge straightener which is what I am trying to use the ceramic hone for ?

I would love to have a simple jig to hold the edge while honing on a ceramic stick or maybe even on a WEPS paddle

08/16/2017 at 12:24 pm #40637The strop will smooth the bevel making it sharper. If your steak knives edges are rolling so much that you’re frequently needing to use the ceramic rod to straighten the edge, maybe you’ve put too narrow a bevel angle on the steak knives. I would expect them to be more durable than your describing, or then I’m understanding. They’re designed with the purpose to be used on hard surfaces like ceramics and porcelain, with little or no maintenance, I would think.

Marc

(MarcH's Rack-Its)08/16/2017 at 2:26 pm #40641What does the edge look like if you sharpen the knife from scratch and then run it over the honing rod before you actually use the knife?

What angle are you applying? A micro-bevel might be the answer.

Stropping is frequently enough to hone the knife if the edge isn’t severely rolled.

Does your Field and Sport have the cam operated vise? If so, I’d favor just using it once a week to pop the knives, lightly touch the micro-bevel with few strokes per side at your finishing grit and call it done without ever using a honing rod.

-Clay

1 user thanked author for this post.

08/16/2017 at 2:44 pm #40642Clay,

I am going to try again tonight and take some pics of the edge after WEPS and then after honing rod. I suspect I will get an imperfect 1000 grit horizontal scratch pattern from the ceramic rod due to my free hand motion.

I am putting a 20 DPS bevel, no micro bevel cause I like the way 20 DPS slices my NY Strip Steak – LOL

The edge is getting rolled / deflected when it hits my dinner plate. I can tell using my thumb nail scrape test and tilting the blade until it scrapes

Field and Sport Pro has the cam setup but I have 8 of these steak knives in use. Doing them all once a week will take an hour. Too long. The ceramic rod takes 10 seconds each.

I would love to have a wedge to ride the plastic shoulders of your handles with a slippery magnet to hold the knife to the wedge and allow simple touch up. If I had the time I would 3d print one at my library for $5.

08/16/2017 at 2:50 pm #40647I like the wedge suggestion, great idea.

I think you might be surprised at how quickly you can touch up the knives if you don’t get too picky about placement in the vise, especially if you thin the shoulders a little, maybe to 17 dps and then add back a 20 dps micro-bevel at your desired finish. Touch-ups should really only require a couple of light strokes at 20 dps with the finishing stone and should only take about 30 seconds each.

-Clay

08/16/2017 at 2:56 pm #40648I find placement in the vise is super critical (via alignment guide) if you want a razor edge on the full curve at the tip. How can you thin the shoulders on WEPS ?

08/16/2017 at 3:13 pm #40649I find placement in the vise is super critical (via alignment guide) if you want a razor edge on the full curve at the tip. How can you thin the shoulders on WEPS ?

For placement, are there any marks, like lasered logo, on the blade that you can align w/ the front or back of the clamp? If so, that might be quicker.

To thin the shoulders, just sharpen the knife at 17 dps until you reach the apex. Then use your finishing stone to make a few, very light passes at 20 dps to set the micro-bevel.

-Clay

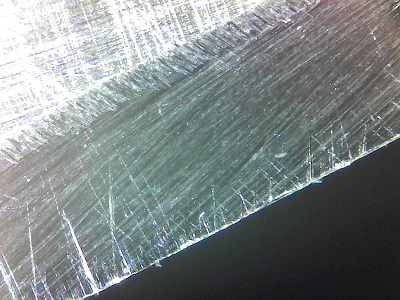

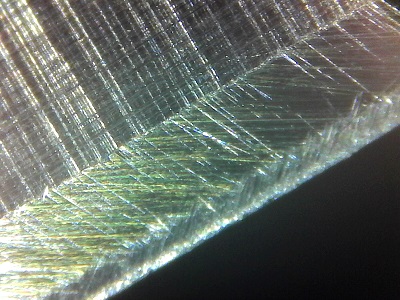

08/16/2017 at 10:31 pm #40657OK, I did a 17,20 DPS (17 DPS bevel and 20 DPS microbevel full reprofile with burr verification) trial on a single steak knife and learned some more. I thank you for your advice. I took sets of pics (left and right side as mounted in WEPS). The first is the before condition (20 DPS with no microbevel).

What I see is that my free hand honing is not reaching the apex at all on one side which bummed me out. I do honing while holding the ceramic rod horizontal (nonstandard) because it is quick and comfortable (obviously my visual angle is much less accurate than I thought). I/we could really use that wedge. I accepted that condition and moved to a 17,20 reprofile.

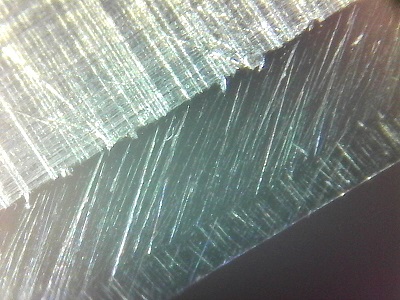

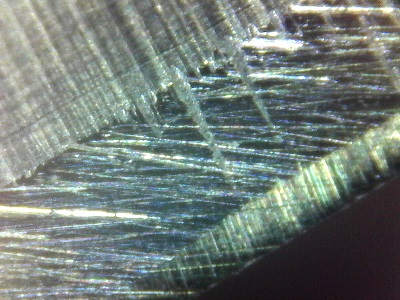

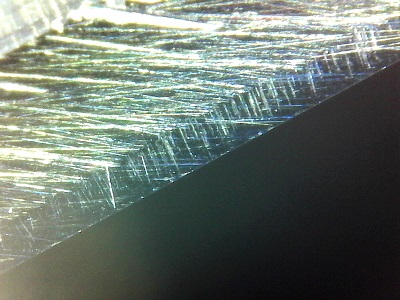

My 17 DPS progression was the full suite (100,200,400,600,800,1000,1500,9um,5,3 AlOx Film,2um strop emulsion,1). My test bed was bent phone book paper and glossy magazine paper. The results shown below were comforting to say the least. I took the 17 DPS to the full suite (even though I knew I would be adding a 20 DPS microbevel as I was curious of the sharpness. I removed the knife from WEPS and the 17 DPS was super sharp passing the test bed with flying colors. I then remounted the knife using the alignment guide (no sharpie) and set the angles using the angle cube (0.5 deg adjustments needed) to 20 DPS. I used only the 1000 grit with 20 passes per side to set the microbevel (pic below). I removed the knife and it the failed test bed miserably.

I then remounted the knife again using the alignment guide (no sharpie) and took the knife thru the rest of the full suite being very careful and light with the strops to avoid the infamous edge roll. The pics below show the final product. I then unmounted the knife and it performed excellent in the test bed. As far as I can tell the 17,20 DPS cut almost as well as when it was at 17 DPS above.

I look to see how it holds up over time against a dinner plate. I will be using my USB scope to monitor my free hand honing until someone comes up with a wedge.

BTW, are you going to the NYC Knife Show on Nov 10,11. The current exhibitors include lots of custom makes but no sharpeners from what I can tell. I am going (my first show) with my WEPS in the car and my USB scope with my phone ready to challenge sharpness, looking for a 8” Kramer style chef knife in S110V. I will be your advocate if you are not there (Jende and Cutlerymania are near me in Jersey).

TY, Tom (Readheads)

Attachments:

You must be logged in to access attached files.

08/17/2017 at 8:07 am #40678I have a set of six Wuesthof steak knives which are very thin and have the same non-serrated edge. Most of the less expensive steak knives are serrated, not to improve their cutting ability, but to keep the sharp sections of the edge from touching the plate. I have suspected for a long while that the Wuesthofs (and probably your Henckels) are much harder than most kitchen knives. We use our steak knives more than any other knife is the drawer, but I only sharpen them maybe twice per year. It’s amazing that they can take such abuse without being dulled horribly.

It might be that the hardness is affecting your sharpening process?

Clearly, your micro-photos look like very sharp edges, but you say they’re failing your paper test. Something is not right at the apex. On your next go-round, inspect your edges with your ‘scope looking straight down on the apex. I have found that it’s easier to see dulling, dents and chips from that overhead perspective.

Worksharp provides a small ceramic hone for touch-ups. They have a 20-degree ramp on the handle for you to use as a reference, since most people cannot accurately guesstimate a repeatable angle. I’ve see this feature on at least one other hone and it seems to me to be an important feature. Can you add something like this to your hone?

08/17/2017 at 9:36 am #40683Redheads – we won’t be at the NY show. We stopped going a couple of years ago because we just weren’t seeing many new people and it’s an expensive show to do given the location.

I’m enjoying your experiment. The micro-bevel won’t give you added strength if it’s set at the same angle as your bevel was previously, but it will make the touch-ups much faster. You might want to try using fewer strokes when forming micro-bevels. I find that I’m very happy with 3-5 per side, whisper-lite strokes. Then maybe a couple light touches with the strops to clean it up. You might get great results applying the micro-bevel with either the 1500# or even the 9µ film and then hitting the edge with 3-5 very light strokes of your 2µ strops. If you try that, I’d love to hear how it goes.

-Clay

08/17/2017 at 11:13 am #40693The microbevel works fine. The interesting thing is after setting the microbevel with the 1000 grit (20 gentle strokes per side) and unmounting the knife, it miserably failed the test bed. Remounting the knife and continuing the full suite on the microbevel (20 gentle strokes per side) resulted in admirably passing the test bed.

I did only 1 knife of the 8. I will do another at 17,20 as Clay described above.

Question: Is there a best practice for measuring sharpness while the knife remains mounted ? It will save time and increase repeatability. It would have to be something which gets cut (in lieu of the 3 finger, etc). I was thinking of a paper straw or phonebook paper roll of a consistent diameter “whacked” into the blade at a 45 deg angle to see if the edge with cut into and slice it.

I guess I could also do an upside down thumb nail scrape.

2 users thanked author for this post.

08/17/2017 at 11:48 am #40695I hold a small square of news paper roughly 4″X4″ by the opposite bottom corners and gently pull it down on the clamped knife edge. I use the amount of pressure I need to apply, the ease it cuts and the smoothness I feel as it cuts, as my gauge for sharpness. After doing this maybe a couple hundred times I can now judge whether my edge is sharp and how sharp it is. When I do this little test throughout the sharpening process I see the progress I’m making. It’s nothing scientific or truly qualitative but done enough times I’ve learned to correlate the feel with the knives’ sharpness.

Marc

(MarcH's Rack-Its)3 users thanked author for this post.

08/17/2017 at 2:38 pm #40720I also use the blade to cut thin magazine paper while the knife is clamped. You simply manipulate the paper rather than the blade.

4 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.