CPM S110V

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › CPM S110V

- This topic has 35 replies, 9 voices, and was last updated 09/18/2017 at 10:39 am by

Mark76.

-

AuthorPosts

-

08/16/2017 at 5:27 pm #40650

I understand that this steel is one of the more difficult to sharpen well. I worked on my Spyderco Manix 2 S110V over the last two days. I am sharpening at 19 DPS. I started with diamond stones, 200/400/600/800/1000/1500. The burr was verified on the 200 and 400 diamond stones, then alternating strokes/direction for the remaining diamond stones, confirming that all previous scratches were removed prior to moving on.

I then moved to chosera water stones. The first was the 2,000 (I know it is a bit of a jump, it took forever, waiting on the 800/1000 to arrive), using the scrubbing motion to eliminate the 1500 diamond scratches, then alternating edge trailing for 100 +/- strokes. I did the same for the 3,000/5,000/10,000 chosera stones. What I noticed was that during the scrubbing, the apex appeared to become rough, rubblized is the best way I can describe it (I wish I had taken pictures). It took a lot of work/time to get a clean edge to the apex.

This problem reappeared with each chosera progression. With each scrubbing session, the rubblization reappeared Any insight? Could the edge leading stroke of the scrubbing have slurry building up, damaging the apex as the stone travels down? Technique?

I finished with the ceramic micro fine, 1.4/0.6, which seemed a waste of time on this steel, and 0.5 micron strop. The blade is sharp cutting paper but very disappointing for what it should be, it won’t shave arm hair at all…

Note: this is the first time I have used the scrubbing motion with the chosera stones. In the past, I used the edge trailing only. I adapted the scrubbing method from the Jende video…

Input appreciated as always!

08/16/2017 at 6:13 pm #40652I think you might find this thread to be relevant to your experience. I may be wrong, but your description sounds similar to what others have experienced and detailed there.

1 user thanked author for this post.

08/16/2017 at 8:40 pm #40655That was very interesting, thanks Organic. So I will conclude that the harder steels, S110V, M390, ZDP189, etc., do not take a highly refined (high grit/polish) edge as well as more ductile steels at the apex. The molecular makeup, being extremely hard and more brittle, has the tendency to chip or “rubblize” as I described it?

That be the case, what grit/angle are these steels being sharpened to with success? Should I stop at the diamond and skip the choseras when dealing with these materials?

08/16/2017 at 9:13 pm #40656My Manix Lightweight S110V was one of the first knives I sharpened, and I thought it was a piece of cake – incredibly easy to get close to a mirror edge on it, and I could “treetop” arm hair with it. Big difference, I think: no water stones. The blade needed reprofiled on the belly forward to the tip. I accomplished the setup with notes for the angle gauge, the reprofile, the sharpening, and the polishing in about 15 minutes.

Reprofile work was done with 100 grit diamond.

Sharpening sequence was 100-200-400-600-800 stones. I alternated edge leading and edge trailing so that I could debug as needed.

After 800, I knocked off the burr, and started a new sequence: 1000-1500 stones, 50 strokes each, no scrubbing.

Then I moved to DLF, and used the 9 micron, for about 50 strokes, and then switched to some horizontal scrubbing, light pressure – basically dividing the blade up visually, and scrubbing from heel to tip and back again, while slowly moving the stone up.

I then switched to stropping. I’m still working on my stropping progressions, but I have this overall plan: start with a diamond paste in the 6-12 micron range, and a “hard” paddle (think something like cereal box on metal paddles). Then we’re going to manipulate a couple variables: surface firmness and grit size, until we get to our final grit/surface/angle adjust combo, which might be something like .1 micron / cow leather / -1.5 degrees.

Along the way, we might discover that this sequence:

3 micron / hard / no change

1 micron / medium / no change

.5 micron / soft-medium / -.5 degree

.25 micron / soft / -1 degree

.1 micron / soft/ -1.5 degreeWhere we can get the hard-med-soft surface from:

Hard: metal (glass) with cereal box strip

Medium: nanocloth

soft-medium: balsa

soft: cow leather / roo leatherI’m working on these progressions now, in fact, just so that I have standards to follow and avoid random creep.

Hope that helps, or gives you some ideas.

Bob

As somebody with advanced terminal cancer, there will be dark days when I complain about things you say for no apparent reason. Please consider this my apology in advance for such times. There will be days that what I say is clearly wrong, making no sense: on these days I will often be argumentative. Please do not "let me slide" at such times, but rather call me out, point out what is factually wrong, and demand I explain my position. Please also consider this my apology in advance for such times.

08/16/2017 at 11:06 pm #40668What do you mean by rubblization ? I am looking for an S110 8 inch chef knife (Kramer style) and the only maker I could find is Houston Edge and he wants $1,200 cause of all the grinding needed with ceramic belts. It sounds to me like you are causing burnishing to happen. It is a somewhat mysterious process to me that you can “move” metal which still remains bonded to the steel matrix. It reminds me of the mystery of scratches reappearing when going to the finer grits. I would classify myself as an amateur metallurgist (Mech Eng by education).

It sure is interesting stuff and BTW is the same kinds of effects that keep us from having metals which can withstand the highest stresses to take us to Mars – LOL !!

08/16/2017 at 11:11 pm #40669Bob, you are all over the map with your descriptions here. How can you do horizontal scrubbing with DLF ? It would rip it up or at the least wear out the DLF surface very quickly.

08/16/2017 at 11:11 pm #40670I have sharpened a handful of M390 / S90V blades thus far and find that they take an extremely keen edge with great polish. No issues with chipping at 20 DPS. My progression is:

100-1500 diamond

6 > 3 > 1 > 0.5 > 0.1 diamond lapping film

Kangaroo strops with 0.25 and 0.1 Jende diamond emulsions (angle lowered to 19 degrees for stropping)

This progression has resulted in hair whittling edges that are very polished. Not a perfect mirror as I do not obsess about removing each and every scratch throughout the progression, but it still results in the sharpest knives I’ve ever used.

08/17/2017 at 12:15 am #40671Bob, you are all over the map with your descriptions here. How can you do horizontal scrubbing with DLF ? It would rip it up or at the least wear out the DLF surface very quickly.

Well, crap. No wonder I have NOT worn out a single piece of DLF, nor ripped it up, after having done, mmmmm, 17 knives using it. I’d better stop doing this.

I’m guessing with your experience, you know more about this than me. Can I ask you how many knives you have used this technique on, and what your usage stats from your log are like? You must keep detailed logs, right?

As somebody with advanced terminal cancer, there will be dark days when I complain about things you say for no apparent reason. Please consider this my apology in advance for such times. There will be days that what I say is clearly wrong, making no sense: on these days I will often be argumentative. Please do not "let me slide" at such times, but rather call me out, point out what is factually wrong, and demand I explain my position. Please also consider this my apology in advance for such times.

08/17/2017 at 1:33 am #40672Rich, I have found a considerable inconsistency in my experience sharpening these “super hard stainless steels”, as I like to call them. One ZDP-189 knife might be a bitch to sharpen and another brand also made of ZDP-189 might be a much easier go. I don’t know whether it has to do with the hardening process. I have no explanation. Then one “SHSS” knife might take and hold a great edge and the other may dull relatively quickly. I can only guess. For me it’s an act in progress. I’m going slow with these knives and I usually strop then again to see if that helps, before trying to re-sharpen it. I have found mixed results with re-stropping.

I do believe after visually inspecting 6 or 8 new, out-of-box, “SHSS” chef’s knives, via USB microscope, that they were all ground and sharpened relatively vertically and not to a very fine grit. Some were surprisingly crude-looking in their sharpening jobs for a knife that felt can cut so sharply. Lately, I’ve only taken the grits down to 4K before stropping with very nice results.

I have been applying 14dps 50/50 even bevels to these knives as I finally sharpen them for the first time. I’ve been told “no diamonds” by some other Forum members, not WE. I’ve only been using whetstones, then strops. My early attempts with diamond stones often ended like your edge! A very well known sharpener from another Forum felt that 14dps was too step for these brittle steels and adding a micro-bevel might be necessary. I haven’t gotten to that point yet.

I have sharpened at least 6 “SHSS”. I have not sharpened S110V, though, so this all may be moot.

Marc

(MarcH's Rack-Its)08/17/2017 at 3:18 am #40675I can imagine that 14 degrees is too steep for such a steel. But why no diamonds? As far as I thought, the most important thing for stones (strops are a little different) is that the abrasive is harder than the steel. So what, in this respect, is the difference between a natural stone and a diamond stone?

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

08/17/2017 at 7:51 am #40677Thank you all for your input. My next step will be to use the chosera 800, edge trailing, and see if I can get the apex “clean”. Then using the same edge trailing technique, attempt to progress up to 10k.

If this fails, I will go to the 1500 diamond and see if I can get a clean apex.

If failure again, I will assume that the edge of the steel has been damaged due to sharpening at the factory, heat, and start clean, re-profile @ 100 grit getting to what I assume will be good, virgin metal, and proceed again.

I have not yet invested in the DLF media but the day may be getting closer…

08/17/2017 at 9:14 am #40681Rich, just sharing my experience, I suffered edge loss usually when using edge trailing strokes. Now I only employ a more vertical angled edge leading, and scrubbing strokes. Just what you said you did in your original post! I usually start with a perpendicular stroke across the apex from heel to tip to heel, to debride the ragged edge and level the fresh metal. Then I begin with 500 grit whetstones doing one sided scrubbing strokes to establish the scratch pattern completely from shoulder to apex, to verify I am fully working the bevel and that I have the clamping position and angle set properly. For me the USB Microscope is a valuable tool.

Then I alternate to the other side and continue with the same one sided scrubbing strokes following my same protocol. I alternate the one sided scrubbing until I can feel with finger touches and I can visually verify with the USB Scope that I am apexing the edge and it’s feeling sharp. I check along the full length of the edge.

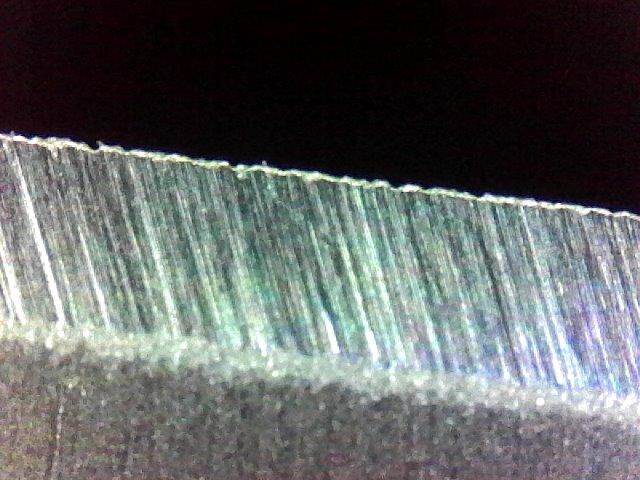

At this point I’ll begin a bilateral alternating edge leading stroke with a mostly vertical and parallel stroke. (I always employ plastic safety shields to protect my finger-tips). I continue to work on small portions of the edge as I move across the entire edge length. The goal is to eventually blend the full length of the edge. When I can feel the sharpness and, again, visually see I have the blended the scratch pattern so it is evenly spaced and aligned parallely, then I’ll move up to the next grit and start the same succession over again. This method allows me to verify I have apexed the edge with out needing to waste any metal working a one-sided burr then switching to a one-sided burr, on the other side. With the 500 grit stone the USB Microscope view is quite chippy:

I repeat this up through 4k, (and sometimes 8K) then move on to the strops. The edge appears smoother and less chippy as I use the finer grits.My reason for suggesting you stay away from diamonds is the scratch pattern of the whetstones are more uniform and predictable in width and depth as you progress up the grits. Also the water cools and lubricates the surface as you use them.

I am doing my own little Diamond Lapping Film Trial now. I can share that the DLF are their name sake, “Diamond Stones”. They behave very much like higher grit, (finer) whetstones in their scratch pattern width and depth. They are just like the praised 1500 WE Diamond Stones, just getting finer. I have spritzed the DLF with soapy water to help lubricate and cool the surface. They do slide easier that way. I loose the feed back, feel, though.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

08/17/2017 at 9:44 am #40684Bob, you are all over the map with your descriptions here. How can you do horizontal scrubbing with DLF ? It would rip it up or at the least wear out the DLF surface very quickly.

Bob is actually onto something here. I often use horizontal strokes and sometimes scrub horizontally with the lapping films. It doesn’t tear them but you need to have something you can adjust on the rod, like a stop collar, to keep the stone in the same position for a period until the film loads up, then move the stop (I just use a rubber band) up a little to work on a fresh section of the film. It works great for polishing but is not good for the edge, so I only do it when I’m planning on either a micro-bevel or finishing with perpendicular strokes on my final DLF grit.

-Clay

08/17/2017 at 9:55 am #40685Bob, you are all over the map with your descriptions here. How can you do horizontal scrubbing with DLF ? It would rip it up or at the least wear out the DLF surface very quickly.

Redhead I recently tried with good success a “vertical” up/down scrubbing stroke with DLF from Jende with great results. I experienced no cutting or shredding of the film at all. Of course I used a very light touch.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

08/17/2017 at 10:04 am #40687Bob, you are all over the map with your descriptions here. How can you do horizontal scrubbing with DLF ? It would rip it up or at the least wear out the DLF surface very quickly.

Bob is actually onto something here. I often use horizontal strokes and sometimes scrub horizontally with the lapping films. It doesn’t tear them but you need to have something you can adjust on the rod, like a stop collar, to keep the stone in the same position for a period until the film loads up, then move the stop (I just use a rubber band) up a little to work on a fresh section of the film. It works great for polishing but is not good for the edge, so I only do it when I’m planning on either a micro-bevel or finishing with perpendicular strokes on my final DLF grit.

Clay, maybe that’s a huge difference in my approach: I switched my mindset from viewing the use of DLF as an exercise in sharpening to that of being an exercise in polishing.

As with all mindsets, generalizations, and abstractions there will be exceptions. However, one of the specific fallouts from my mindset change is that your observation of horizontal scrubbing being bad for edges elicits a “So what – it makes the edge look better” from me. Ultimately, I think, I will have to deal with combining the two perspectives: maybe I’ll end up using 75% less horizontal scrubbing, finding that it gives me 80% of an improvement in looks, and only negatively impacts the edge by 10%. If I instead use 90% horizontal scrubbing, I might get an 85% improvement in looks, but a negative impact to the edge of 75%.

But I have to start somewhere.

As somebody with advanced terminal cancer, there will be dark days when I complain about things you say for no apparent reason. Please consider this my apology in advance for such times. There will be days that what I say is clearly wrong, making no sense: on these days I will often be argumentative. Please do not "let me slide" at such times, but rather call me out, point out what is factually wrong, and demand I explain my position. Please also consider this my apology in advance for such times.

-

AuthorPosts

- You must be logged in to reply to this topic.